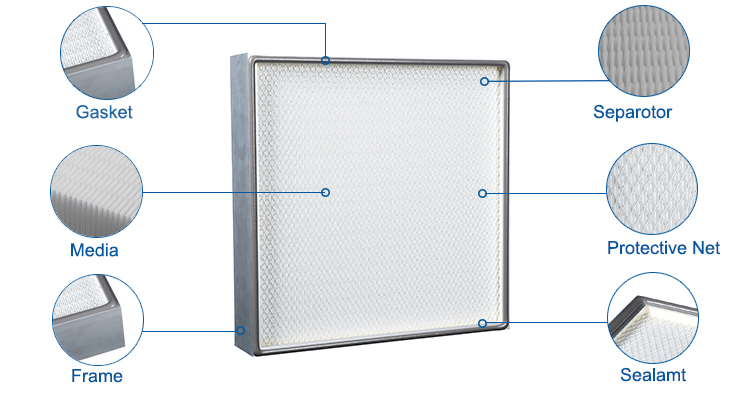

Filter media: Glass fiber / PTFE / PP

Frame: MDF / Aluminum

Gasket: EPDM / EVA / PU foamed

Separator: Hot-melt adhesive

Max.working temperature: 70℃

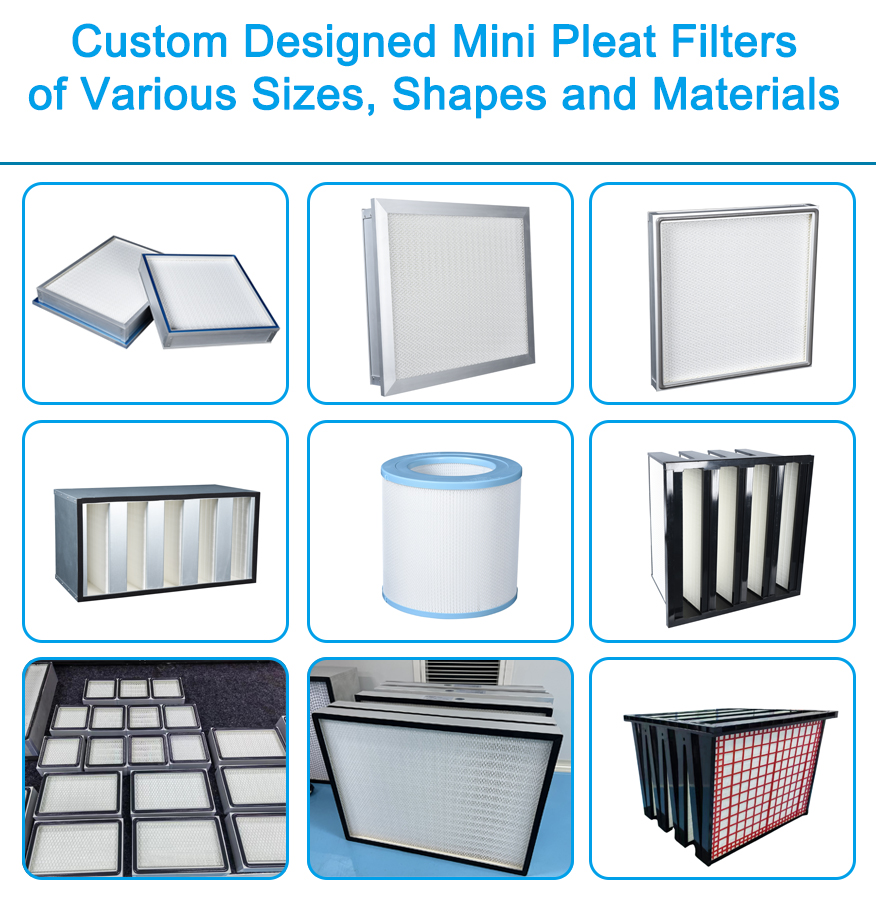

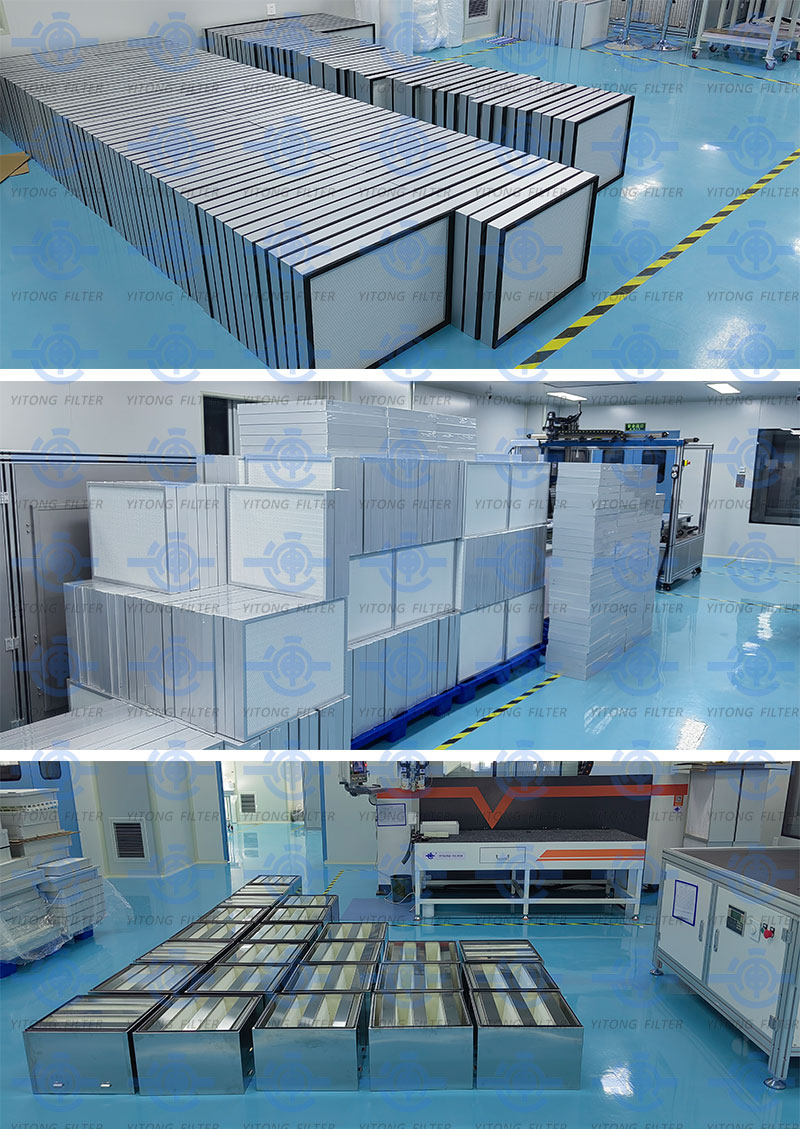

The Mini pleat hepa filter mainly uses hot melt adhesive as the separator, which facilitates mechanized production. It has the advantages of being compact, lightweight, easy to install, having stable efficiency, and providing uniform airflow. Currently, large quantities of filters required for clean factories and places with high cleanliness requirements mostly use separatorless structures. Nowadays, Class A clean rooms generally choose mini-pleat hepa filters, and the FFU are also equipped with mini-pleat hepa filters. Compared with the separator type high-efficiency filters, under the same airflow volume, mini-pleat hepa filters have the benefits of being smaller in size, lighter in weight, more compact in structure, and more reliable in function, with the equipment providing stable efficiency and uniform airflow.

1. High filtration efficiency, lightweight, and compact structure

2. Corrosion-resistant and resistant to microbial growth

3. Long service life and low operating costs

| Size (mm)(W×H×D) | Rated airflow (m³/h) | Face velocity (m/s) | Clean pressure drop (Pa) | Final pressure drop (Pa) | |||

| H10 | H11 | H13 | H14 | ||||

| 305×610×50 | 800 | 1.2 | 120 | 180 | 250 | 270 | 2-2.5 times of clean pressure drop |

| 610×610×50 | 1600 | 12. | 120 | 180 | 250 | 270 | |

| 610×610×70 | 1600 | 1.2 | 85 | 145 | 220 | 240 | |

| 1170×570×70 | 2800 | 1.2 | 85 | 145 | 220 | 240 | |

| 610×610×80 | 1600 | 1.2 | 75 | 135 | 215 | 230 | |

| 610×915×80 | 2400 | 1.2 | 75 | 135 | 215 | 230 | |

Support Customization

If you are interested in any of our products, please feel free to contact us, our team will provide you with professional service and perfect quotation!

Terminal air outlets in clean rooms, FFU, and clean equipment