Main function: Clarify filtration

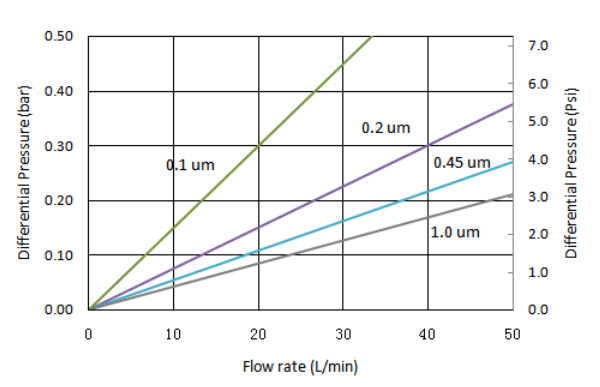

Typical Flow Characteristics @25℃(10")

Note:

This chart represents typical water flow per 10" cartridge length.

The test fluid is water at ambient temperature. Extrapolation for

multiple elements tends to be linear, but as flows increase the P of the housing becomes more apparent.

| Outer diameter | 60/64/68/70mm |

| Inner diameter | 33mm |

| Effective filter area | ≥0.65㎡/10in |

| Maximum operating temperature | 80 ˚C / 176 ˚F |

| Maximum forward differential pressure | 0.4MPa @ 23 ˚C /58.8 psid @ 73.4 ˚F |

| Steaming sterilize | 121℃/30min |

Polypropylene pleated filter cartridges, or PP filter cartridges, are created with a high surface area polypropylene medium(PP microporous membrane). This ensures low initial pressure drop and high dirt holding capacity, making it an efficient membrane pre-filter and a suitable final polishing filter for many fluid refining processes. Furthermore, cartridges are manufactured with a heavy-duty molded cage, which allows them to endure high-pressure drops.

1. From 1 to 100 μm, the micron ratings offer a wide range of applications.

2. Made of polypropylene, it is inert to many process fluids, ensuring high chemical compatibility.

3. To meet different requirements, it also comes with various gasket/O-ring materials.

4. The heavy-duty molded cage offers increased structural strength, and the thermally welded construction maximizes durability.

5. The PP microporous membrane provides optimal filtration performance and extended service life.

1. Prefiltration in chemical industry.

2. Prefiltration in pharmaceutical industry, the processing of injections.

3. Prefiltration in food and beverage industry.