July 18, 2023

July 18, 2023

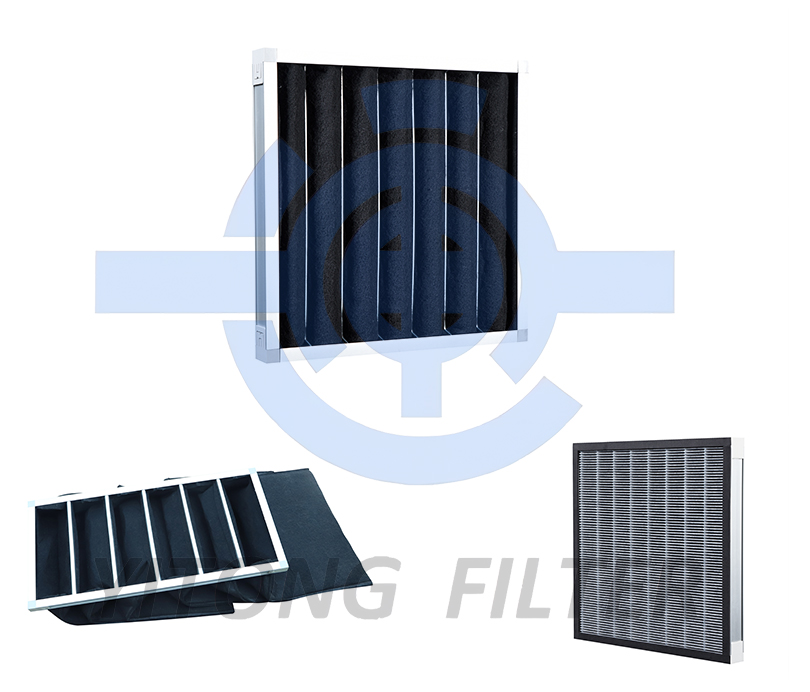

Activated carbon filters are a commonly used filtration device that can be applied in various industries and can meet the needs of different applications effectively. In industrial settings, activated carbon filters are particularly common. The main reason is that the activated carbon in these filters can adsorb organic substances, bacteria, microorganisms, and colloidal substances in water. It can also adsorb non-metallic substances such as bromine and iodine. Moreover, activated carbon filters can remove metal ions like silver, arsenic, and mercury, as well as certain colored substances and odors.

Key Features of Activated Carbon Filters:

1. Stability: Activated carbon filters operate with great stability. With fewer moving parts apart from the filtering material, the probability of failure is relatively low. When used with a certain concentration of filtering material for an extended period, the activated carbon filter maintains consistent and stable performance.

2. Low Operating Costs: Activated carbon filters do not require backflow pumps or electric valves to operate, resulting in minimal workload. Additionally, since they use a single filtering material, if cleaned promptly, the head loss will be relatively low, eliminating the need for high head and high flow backflow pumps and reducing operation and maintenance costs.

3. Versatility: Activated carbon filters are highly adaptable. In situations where higher filtering requirements exist, using a single filter might not suffice. In such cases, combining multiple filtering facilities can be cumbersome. However, with activated carbon filters, the workload can be significantly reduced due to their strong adaptability, allowing for quick expansion or reduction of other filtering equipment.

Precautions for Using Activated Carbon Filters:

1. Understand Adsorption Mechanism: It is essential to grasp the adsorption mechanism of activated carbon filters, which mainly relies on adsorbing organic substances onto the carbon surface. As water flows through the carbon bed, the adsorption capacity of activated carbon diminishes due to crystalline accumulation, leading to a decline in its effectiveness. High organic content in water can accelerate the deactivation of activated carbon, rendering the filtering effect ineffective. Thus, regular cleaning or replacement of the filtering material in the activated carbon filter is necessary.

2. Proper Installation and Usage: During the transportation, installation, and usage of activated carbon filters, it is crucial to follow the requirements to ensure their effectiveness. To maximize the performance of activated carbon filters, it is recommended to set the wind speed not exceeding 2.5 m/s, as this facilitates their operation, guarantees filtering efficiency, prolongs usage, and saves costs.

3. Timely Replacement: If an activated carbon filter is due for replacement but cannot be stopped for replacement, it is acceptable to replace it with an initial or medium-efficiency activated carbon filter without shutting down the blower. However, high-efficiency and super high-efficiency activated carbon filters must be replaced after ten weeks of inactivity at the air outlet.

4. Consider Environmental Factors: In environments with high temperatures and humidity, it is necessary to use activated carbon filters with filter papers and partitions that can withstand such conditions. In laboratories, biological cleanrooms, pharmaceutical cleanrooms, etc., it is advisable to choose activated carbon filters with metal frames, as they are less susceptible to corrosion and rust. Wooden frames may foster bacterial growth, which can affect the product qualification rate in cleanrooms.

To achieve optimal performance with activated carbon filters, pay attention not only to their characteristics but also to adjusting work plans or modes appropriately. Moreover, ensure proper usage, regular cleaning, and maintenance of the filters to maintain their effectiveness over time.

Dec. 25, 2024

Box Type HEPA Filter

Dec. 25, 2024

Box Type HEPA Filter

Jan. 11, 2024

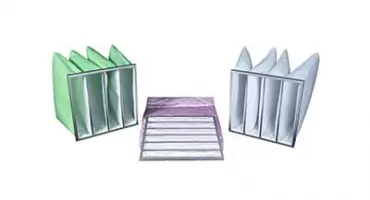

Enhancing Air Quality with Pocket Air Filters

Jan. 11, 2024

Enhancing Air Quality with Pocket Air Filters

Feb. 10, 2025

HEPA Filters for HVAC: What You Need to Know

Feb. 10, 2025

HEPA Filters for HVAC: What You Need to Know