December 24, 2024

December 24, 2024

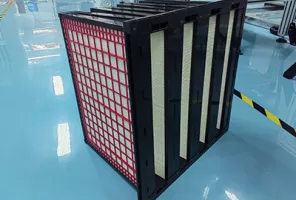

Cleanroom filters are critical components in various industries, ensuring that the air within controlled environments meets stringent cleanliness standards. From pharmaceutical manufacturing to electronics production, these filters help maintain product quality and safety. In this guide, we’ll answer the most common questions about cleanroom filters, providing clear, accessible insights.

Cleanrooms rely on a combination of filters to achieve the desired level of air purity. Here are the primary types:

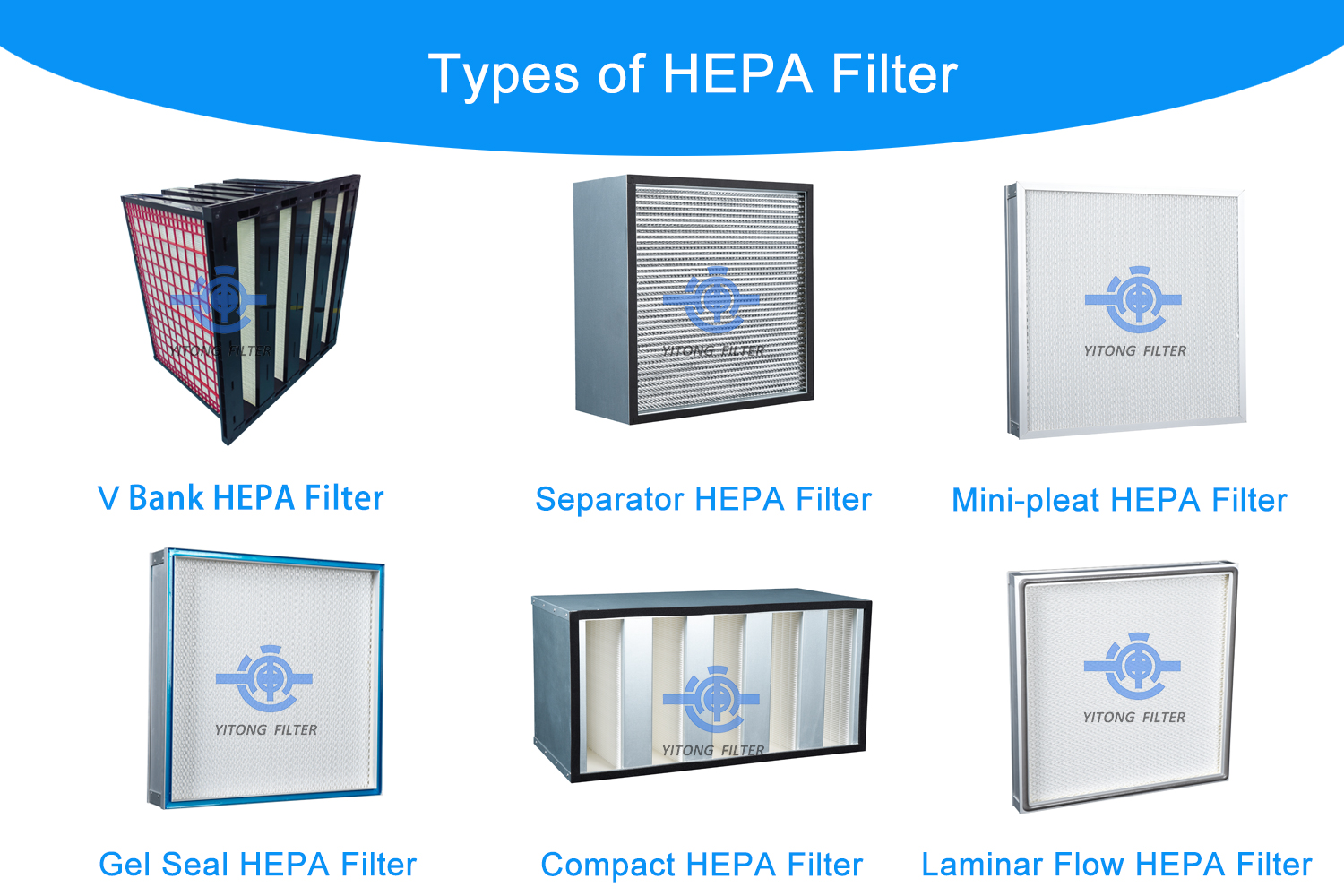

High-Efficiency Particulate Air (HEPA) filters are designed to capture particles as small as 0.3 microns with at least 99.97% efficiency. These are the most commonly used filters in cleanrooms.

ULPA Filters

Ultra-Low Penetration Air (ULPA) filters offer even higher efficiency, capturing particles as small as 0.1 microns with at least 99.999% efficiency. These are used in environments that require exceptional cleanliness, such as semiconductor manufacturing.

Pre-filters are used to remove larger particles before the air reaches the HEPA or ULPA filters. This extends the lifespan of the primary filters and reduces maintenance costs.

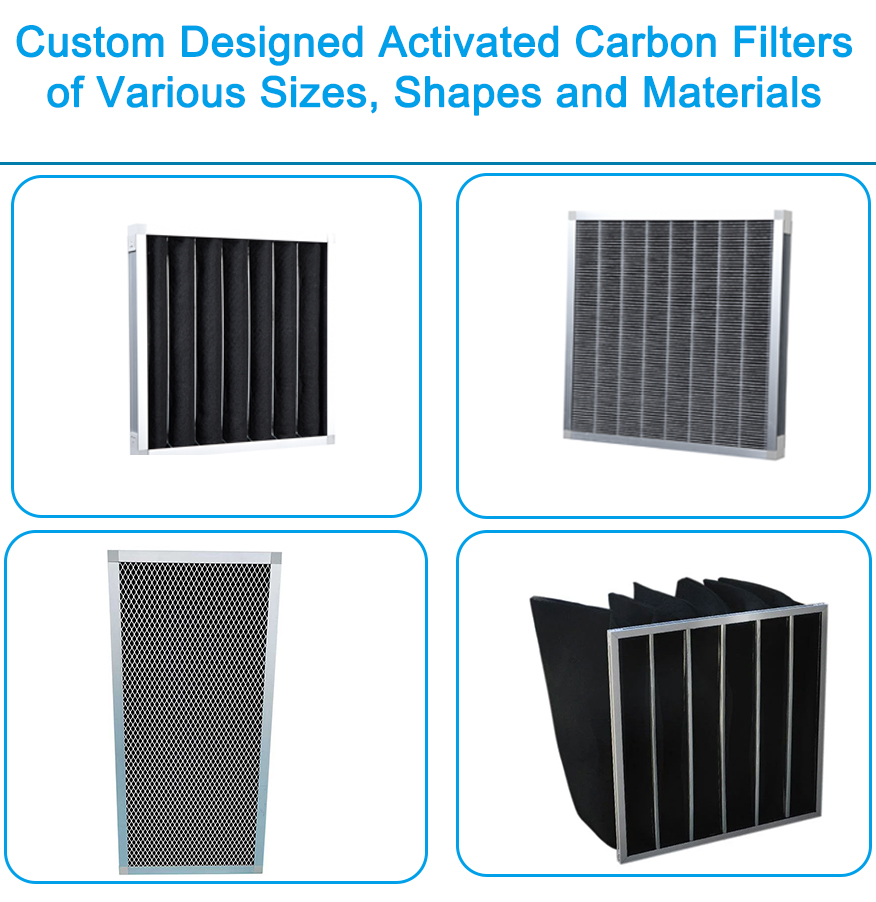

While not standard in all cleanrooms, activated carbon filters are sometimes used to remove gaseous contaminants and odors, especially in industries like pharmaceuticals and food processing.

Cleanroom filters operate on several principles to capture contaminants effectively:

Mechanical Filtration

This involves trapping particles in the filter media. Larger particles are blocked outright, while smaller ones are captured through interception or diffusion.

Electrostatic Attraction

Some filters use electrostatic forces to attract and capture particles, enhancing efficiency without increasing resistance.

Airflow Management

Cleanroom filters are designed to work within specific airflow systems, ensuring that purified air circulates evenly while maintaining laminar flow.

The replacement frequency of cleanroom filters depends on several factors:

Operating Environment

Filters in high-contamination environments, such as pharmaceutical production, may need more frequent replacement compared to those in less demanding settings.

Pressure Drop

A significant increase in pressure drop across the filter indicates it’s becoming clogged and needs replacement.

Regular Testing

Routine inspections, including airflow and integrity tests, help determine whether a filter is still functioning effectively.

In general, pre-filters may need replacement every 3 to 6 months, while HEPA and ULPA filters can last 1 to 3 years with proper maintenance.

Testing cleanroom filters is crucial to ensure they meet performance standards. Common testing methods include:

DOP/PAO Testing

This involves introducing a challenge aerosol, such as Dioctyl Phthalate (DOP) or Polyalphaolefin (PAO), to verify the filter’s efficiency in capturing particles.

Air Velocity Testing

Air velocity across the filter’s surface is measured to ensure uniform airflow.

Pressure Drop Measurement

Pressure drop tests identify resistance levels, which can indicate blockages or other issues.

Cleanroom filters are indispensable in several industries:

Pharmaceuticals

In drug manufacturing, cleanroom filters prevent microbial contamination, ensuring product safety and compliance with regulatory standards.

Electronics and Semiconductors

Filters maintain ultra-clean environments to prevent defects caused by dust or other particles.

Food Processing

Cleanroom filters help maintain hygiene and prevent cross-contamination in food production facilities.

Healthcare

Operating rooms and medical device manufacturing facilities use cleanroom filters to ensure sterile conditions.

Cleanroom filters must meet specific standards to ensure their performance:

ISO Classifications

The ISO 14644 standard defines cleanliness levels for cleanrooms. HEPA and ULPA filters are typically required for ISO Class 5 and above.

EN 1822

This European standard categorizes filters based on their particle retention efficiency, from coarse filters to HEPA and ULPA grades.

ASHRAE 52.2

This American standard focuses on the Minimum Efficiency Reporting Value (MERV) rating, providing a benchmark for filter performance.

Yes, cleanroom filters can effectively capture viruses and bacteria:

HEPA Filters

HEPA filters are highly effective at trapping airborne microorganisms due to their small particle size capture capability.

ULPA Filters

ULPA filters offer even greater efficiency, making them suitable for environments requiring sterility, such as biosafety labs.

It’s important to note that while filters capture pathogens, additional measures like UV sterilization may be required to neutralize them.

The cost of cleanroom filters varies widely based on several factors:

Type of Filter

ULPA filters are generally more expensive than HEPA filters due to their higher efficiency.

Size and Specifications

Larger filters or those designed for high-performance applications will typically cost more.

Replacement and Maintenance

While upfront costs are important, consider the long-term costs of replacement and maintenance when choosing a filter.

Proper installation and maintenance are crucial for filter performance:

Installation

- Ensure the filter is compatible with the housing.

- Use proper sealing techniques to prevent leaks.

Maintenance

- Conduct regular inspections for damage or clogging.

- Replace pre-filters to prolong the life of primary filters.

While cleanroom filters are highly effective, they come with challenges:

Increased Pressure Drop

As filters collect particles, pressure drop increases, which can strain the HVAC system.

Environmental Conditions

High humidity or chemical exposure can degrade filter performance.

Balancing Cost and Performance

Choosing a filter that meets cleanliness requirements without excessive costs requires careful consideration.

Cleanroom filters play a vital role in maintaining the integrity of controlled environments. By understanding their types, functions, and maintenance requirements, industries can ensure optimal performance and compliance with cleanliness standards. Whether you’re selecting a filter or troubleshooting an existing system, this guide provides the foundational knowledge needed to make informed decisions.

Jul. 25, 2024

Understanding HEPA Filter H13: Superior Air Purification

Jul. 25, 2024

Understanding HEPA Filter H13: Superior Air Purification

May. 13, 2024

The Importance of HEPA Filters in Ventilation Systems

May. 13, 2024

The Importance of HEPA Filters in Ventilation Systems

Jun. 27, 2025

What Is an F7 Air Filter? A Complete Guide for Clean Air Solutions

Jun. 27, 2025

What Is an F7 Air Filter? A Complete Guide for Clean Air Solutions