August 22, 2024

August 22, 2024

The presence of tiny particles in the air can damage our health, so government agencies have very strict requirements for the cleanliness of the air in some specific places, therefore, H14 hepa filter is favored by more and more people in the industry.

H14 filter is an air filter efficiency level in EN1822, the filtration efficiency is usually 99.9995%, which can remove 0.1μm particles in the air, generally used in medical environments, such as Operating Room, laboratories and medical equipment, and other environments that have super high requirements for air quality.

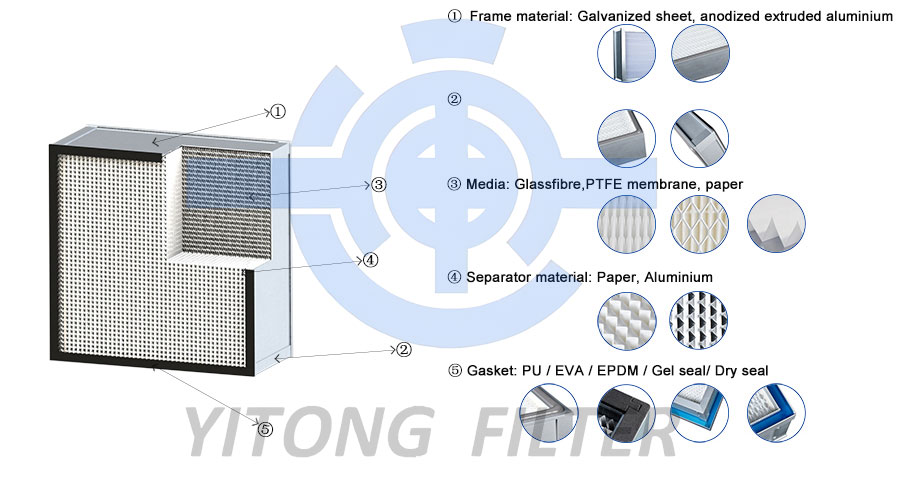

Type: Separator, mini-pleat

Frame material: Galvanized sheet, anodized extruded aluminum, wood, stainless steel

Media: Glassfibre, PTFE membrane

Separator material: Paper, Aluminum

Gasket: PU / EVA / EPDM / Gel seal / Dry seal / Knife edge

H14 filter has better filtration performance than lower grade filters.

H14 HEPA Filter is called medical grade HEPA filter, which can filter 99.9995% of 0.1μm particles in the air. It is usually used in environments that need to be clean, such as medical device manufacturing and electronic equipment manufacturing, which have very high environmental requirements, so H14 filter is a good choice.

For more information about the difference between H13 and H14 HEPA filters, please click here.

HEPA H14 Filter, i.e. high efficiency air filter, has significant advantages, which are mainly reflected in the following aspects:

First, high filtration efficiency

Filtration precision: The filtration efficiency of HEPA H14 Filter is as high as 99.9995%, which can effectively remove dust, bacteria, viruses and other particles in the air, especially for particles above 0.3 microns with very high filtration capacity. This high-precision filtration effect ensures the cleanliness of indoor air.

Second, good stability and long life

High-quality materials: made of high-quality materials with good stability and durability, it can run for a long time and stably, reducing the downtime caused by equipment failure.

Long life: the filter material is made of high quality material, which has a long service life and reduces the frequency and cost of replacing the filter material, thus reducing the overall operation cost.

Third, low resistance and energy saving and environmental protection

Advanced design: the use of advanced design concepts, so that the air flow resistance is minimized, reducing the energy consumption of the ventilation system, saving energy.

Environmental benefits: low resistance characteristics not only reduces energy consumption, but also reduces the pollution of the environment, in line with the environmental requirements of modern society.

Fourth, easy installation and maintenance

Compact structure: HEPA H14 Filter is compact and easy to install, and can be widely used in various clean projects.

Convenient maintenance: Due to its long life and low resistance, it reduces the frequency of maintenance and replacement and lowers the maintenance cost.

V. Wide range of applications

Multi-field application: HEPA H14 Filter can be applied in places with extremely high requirements for air quality, such as electronics, pharmaceuticals, biotechnology, medical equipment, food processing and other fields. In these fields, it can effectively protect products from contamination and improve product quality and productivity.

Health protection: In places such as biosafety facilities, the use of HEPA H14 Filter can effectively remove bacteria, viruses and other harmful substances from the air, protecting the health and safety of personnel.

In summary, HEPA H14 Filter has become an important equipment in the field of modern air purification with its advantages of high filtration efficiency, good stability and long service life, low resistance and energy saving and environmental protection, easy installation and maintenance, as well as a wide range of application areas.

The importance of the H14 HEPA Filter (High Efficiency Particulate Air Filter, class H14) is self-evident, and it plays a vital role in many areas of modern society. Below are a few key aspects of the importance of the H14 HEPA Filter:

1. Safeguarding air quality

With its extremely high filtration efficiency (99.9995% or more), the H14 HEPA Filter is able to effectively remove tiny airborne particles, including dust, pollen, bacteria, viruses, mold spores, and more. This is critical for locations that require a high cleanliness air environment, such as hospital operating rooms, biopharmaceutical laboratories, and semiconductor manufacturing plants, to prevent air contaminants from causing harm to products or human health.

2. Promoting health and safety

In the medical field, the application of H14 HEPA Filter can prevent air pollution in critical areas such as operating rooms, reduce the risk of post-operative infections, and safeguard the lives of patients. Meanwhile, in biosafety laboratories, it can effectively prevent the spread of harmful microorganisms and protect the safety of experimenters and the environment.

3. Improve production efficiency and product quality

In industrial production, dust and particles in the air may cause contamination to the products on the production line and affect product quality. the use of H14 HEPA Filter can significantly reduce this risk and improve the yield rate of products and production efficiency. For example, the use of H14 HEPA Filter is critical in industries such as electronic components, precision instruments and pharmaceutical manufacturing.

4. Energy Saving and Environmentally Friendly

Although the H14 HEPA Filter itself may consume a certain amount of energy during operation, its highly efficient filtration performance allows the entire ventilation system to operate with lower energy consumption. This is because the air is cleaner after being filtered by the H14 HEPA Filter, reducing the amount of energy required for subsequent treatment. In addition, its long life and low replacement frequency also reduce overall operating costs and meet the requirements of energy saving and environmental protection.

5. Compliance with regulations and standards

In many industries and fields, such as pharmaceutical, medical, food processing, etc., there are strict air quality standards and regulations, and the use of H14 HEPA Filter can ensure that the air quality in these places complies with the relevant regulations and standards, avoiding legal risks and business losses caused by air quality problems.

To summarize, H14 HEPA Filter has irreplaceable importance in safeguarding air quality, promoting health and safety, improving productivity and product quality, saving energy and environmental protection, as well as complying with regulations and standards. It is one of the indispensable air purification equipment in modern society.

Technical datasheet

| Model | Type | Material | Size(mm)(WxHxD) | Air flow(m³/h) | Initial pressure(≤Pa) | Filteration area(m²) | Velocity(m/s) | Filteration grade(EN1822-4) |

| YTGX | No separator(W) | Fiber glass (BX) | 610x305x69 | 500 | 90 | 4.92 | 0.75 | H14 |

| (PTFE) | 610x610x69 | 1000 | 90 | 9.84 | 0.75 | H14 | ||

| 915x610x69 | 1500 | 90 | 14.77 | 0.75 | H14 |

Note: More specifications can be customized

H14 Filter, one of the highest grade of High Efficiency Particulate Air Filter (HEPA Filter), has a very high filtration efficiency and a wide range of applications. The following are some of the main applications of H14 Filter:

H14 Filter, one of the highest grade of High Efficiency Particulate Air Filter (HEPA Filter), has a very high filtration efficiency and a wide range of applications. The following are some of the main applications of H14 Filter:

1. Healthcare

Operating Rooms: H14 Filter is widely used in operating rooms to ensure air cleanliness during surgery and reduce the risk of post-operative infections.

Wards and ICUs: In wards and intensive care units (ICUs) that require a highly sterile environment, H14 Filter can effectively remove airborne bacteria, viruses and other microorganisms to protect patients from infection.

Biosafety Laboratory: In laboratories dealing with highly pathogenic microorganisms, H14 Filter is the key equipment to prevent the spread of pathogens.

2. Pharmaceutical and biotechnology industries

Aseptic Production Areas: In the pharmaceutical process, especially in areas where sterile preparations are manufactured, the use of H14 Filters is critical to ensure that the cleanliness of the production environment is in accordance with GMP (Good Manufacturing Practice) requirements.

Laboratory Research: In biotechnology and life science laboratories, H14 Filters are used to protect laboratory personnel from harmful microorganisms and to maintain the accuracy of experimental results.

3. Precision Manufacturing

Electronic component production: In the production process of semiconductors, integrated circuits and other precision electronic components, H14 Filter can prevent airborne particles from contaminating the products and improve product yield and reliability.

Optical instruments and precision machinery: In the manufacturing of optical instruments, precision machinery and other fields, the application of H14 Filter helps to maintain the cleanliness of the production environment and reduce the impact of dust on product performance.

4. Food processing and packaging

Clean room: In the process of food processing and packaging, H14 Filter helps to maintain the cleanliness of the air in the production plant, preventing food contamination and ensuring food safety.

Aseptic Packaging: In the field of food and pharmaceuticals that require aseptic packaging, the application of H14 Filter is critical to maintaining the cleanliness of the packaging environment.

5. Air Purification Systems

Commercial and Residential Air Purification: Although H14 Filter is less commonly used directly in commercial and residential air purification systems (due to its higher cost), similar high-efficiency filtration technology may be used in special locations where air quality is critical, such as museums and libraries.

Industrial Ventilation Systems: In industrial ventilation systems, the H14 Filter can be used as a key component to ensure that the air emitted into the environment meets environmental standards.

In summary, H14 Filter plays an important role in many industries in modern society due to its excellent filtration efficiency and wide range of applications.

When cleaning H14 Filter (i.e. HEPA Filter with H14 rating), you need to pay special attention to its material and filtration efficiency to ensure that its filtration performance will not be damaged during the cleaning process. The following are some suggested cleaning steps and precautions:

I. Preparation before cleaning

Power off and disassembly: First of all, make sure the air purifier or related equipment has been powered off, and disassemble the H14 Filter correctly according to the equipment manual or manufacturer's instructions.

Preparation tools: Prepare a vacuum cleaner (with soft bristle brush head), clean rags or paper towels, and soft brushes that may be needed (e.g. for cleaning stubborn stains).

II. Cleaning Steps

Initial Dusting: Use a vacuum cleaner (with a soft-bristle brush head) to gently remove dust and particles from the surface of the H14 Filter. Avoid using strong suction to avoid damaging the filter media.

Detailed cleaning: For corners or stubborn stains that are hard to reach with a vacuum cleaner, use a soft brush to gently brush away the dust on the surface. Do not use excessive force as the bristles may puncture the filter media.

INSPECTION AND REPLACEMENT: During the cleaning process, carefully inspect the H14 Filter for damage or deformation. If any obvious damage is found or filtration efficiency is significantly reduced, the Filter should be replaced with a new one in time.

III. Precautions

Avoid washing: H14 Filter is usually made of precision filter material and cannot be washed. Washing will damage the structure and filtration performance of the filter material, resulting in Filter failure.

Avoid chemical cleaners: Do not use any chemical cleaners or solvents to clean the H14 Filter. these chemicals may damage the material and performance of the filter media.

Keep Dry: Ensure that the H14 Filter remains dry during cleaning and storage. Humid conditions can accelerate deterioration and damage to the filter media.

Replace regularly: Although the H14 Filter can be cleaned to prolong its service life, the filtration efficiency of the Filter will gradually decrease with the time of use. Therefore, it is recommended to regularly replace the Filter with a new one according to the manufacturer's recommended schedule.

Professional Maintenance: If you are not familiar or sure about cleaning and replacing H14 Filter, it is recommended to seek professional help. They can provide more accurate guidance and advice to ensure the Filter cleaning and replacement process goes smoothly.

In conclusion, special care and caution is required when cleaning H14 Filter to ensure that its filtration performance is not impaired. Following the above steps and precautions will prolong the life of the Filter and maintain the cleanliness of the indoor air.

Jun. 06, 2023

Introduction to Laminar Flow HEPA Filter

Jun. 06, 2023

Introduction to Laminar Flow HEPA Filter

Jun. 13, 2024

Comprehensive Guide to Panel Air Filters

Jun. 13, 2024

Comprehensive Guide to Panel Air Filters

Dec. 07, 2023

The Functionality and Applications of HEPA Filters

Dec. 07, 2023

The Functionality and Applications of HEPA Filters