February 26, 2024

February 26, 2024

In the realm of stringent cleanliness standards, particularly within industries like pharmaceuticals, biotechnology, and microelectronics, maintaining an environment free from contaminants is paramount. Cleanrooms, specially controlled environments designed to minimize particulate contamination, rely on cutting-edge technology to ensure the purity of the air within them. One such technology crucial to this endeavor is the Cleanroom HEPA Fan Filter Unit (FFU).

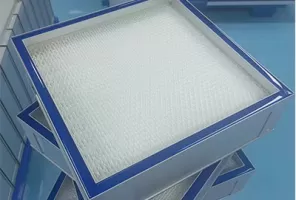

HEPA, or High-Efficiency Particulate Air, filtration is renowned for its ability to capture airborne particles with exceptional efficiency. HEPA filters consist of a dense arrangement of fibers that trap particles as air passes through them. To qualify as a true HEPA filter, it must capture at least 99.97% of particles measuring 0.3 microns in diameter. This standard ensures the removal of a wide range of contaminants, including bacteria, viruses, dust, and other microscopic pollutants.

Fan Filter Units serve as the cornerstone of cleanroom air filtration systems. These units integrate HEPA filters with powerful fans, creating a robust mechanism for circulating and purifying air within the cleanroom. By drawing in contaminated air and passing it through the HEPA filter, FFUs effectively remove particulates, ensuring that the air circulated back into the cleanroom meets the required cleanliness standards.

High Filtration Efficiency: Cleanroom HEPA FFUs are equipped with HEPA filters that meet or exceed the stringent standards set for air purity. With their exceptional filtration efficiency, these units effectively eliminate particles as small as 0.3 microns, safeguarding the cleanroom environment from contaminants.

Uniform Airflow Distribution: Proper airflow distribution is critical in maintaining consistent cleanliness levels throughout the cleanroom. Cleanroom HEPA FFUs are designed to provide uniform airflow, preventing the formation of dead zones where contaminants could accumulate.

Low Energy Consumption: Despite their powerful air circulation capabilities, modern Cleanroom HEPA FFUs are engineered for energy efficiency. Advanced fan designs and motor technologies ensure optimal performance while minimizing energy consumption, contributing to sustainability efforts and reducing operational costs.

Low Noise Operation: In environments where noise levels must be kept to a minimum, such as laboratories or research facilities, Cleanroom HEPA FFUs offer quiet operation without compromising airflow performance. This feature enhances the comfort of personnel working within the cleanroom while maintaining productivity.

Easy Installation and Maintenance: Manufacturers recognize the importance of minimizing downtime in cleanroom operations. Cleanroom HEPA FFUs are designed for easy installation and maintenance, allowing for swift filter replacement and servicing without disrupting critical processes.

Cleanroom HEPA FFUs find application in a diverse range of industries where maintaining a controlled environment is essential. Some common applications include:

Pharmaceutical manufacturing facilities

Biotechnology research laboratories

Semiconductor cleanrooms

Hospital operating rooms and isolation wards

Food and beverage processing plants

Conclusion:

Cleanroom HEPA Fan Filter Units play a pivotal role in upholding the stringent cleanliness standards required in controlled environments. By leveraging the exceptional filtration efficiency of HEPA technology, these units ensure that the air circulating within cleanrooms is free from contaminants, safeguarding sensitive processes and products against contamination. With their advanced features and versatile applications, Cleanroom HEPA FFUs continue to be indispensable assets in industries where air quality is of paramount importance.

Aug. 27, 2024

Air Filtration in Cleanrooms

Aug. 27, 2024

Air Filtration in Cleanrooms

Mar. 08, 2024

The Crucial Role of Medical Grade HEPA Filters in Health Facilities

Mar. 08, 2024

The Crucial Role of Medical Grade HEPA Filters in Health Facilities

Aug. 09, 2023

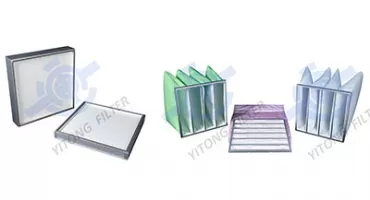

Differences between F8 and F6 Medium Efficiency Filters

Aug. 09, 2023

Differences between F8 and F6 Medium Efficiency Filters