November 11, 2024

November 11, 2024

Clean air is essential in many industries, from healthcare and pharmaceuticals to electronics manufacturing and food processing. In these fields, even tiny contaminants in the air can compromise product quality, patient health, and overall safety. To meet the high demands for clean air, companies often rely on fan filter units (FFUs) equipped with HEPA filters. In this article, we’ll explore what fan filter units with HEPA filters are, how they work, and why they are so widely used in controlled environments.

A Fan Filter Unit (FFU) is a self-contained device that combines a fan and a filter into a single unit. The fan draws air through the filter, removing particulates, contaminants, and pollutants from the air before it enters a controlled environment. FFUs are widely used in cleanrooms and other spaces where air cleanliness is critical. They can be installed in ceilings, walls, or as part of standalone equipment, depending on the facility's requirements.

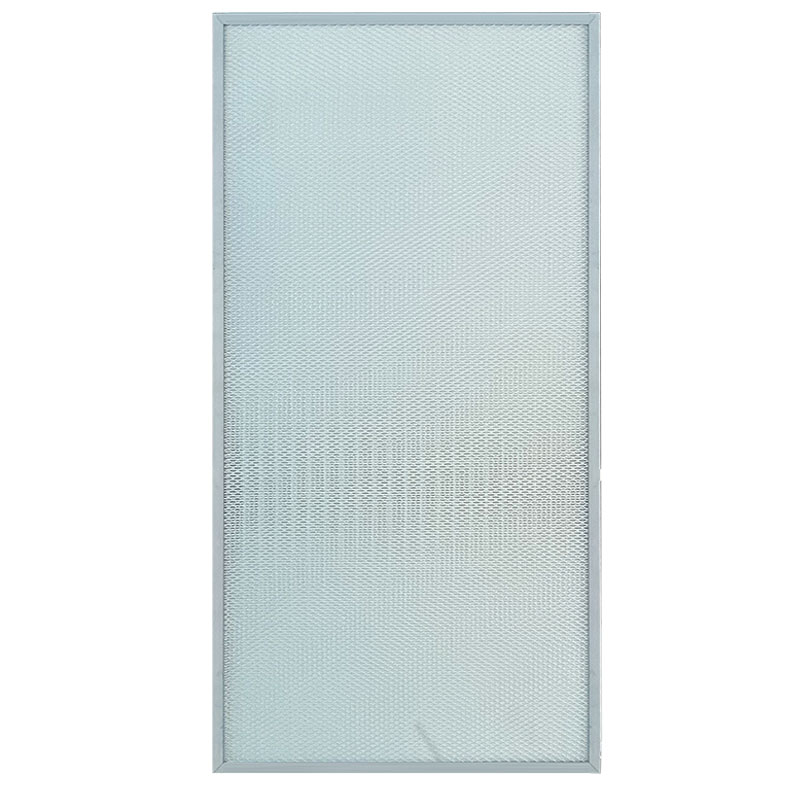

High-Efficiency Particulate Air (HEPA) filters are a crucial component of FFUs. HEPA filters are capable of capturing 99.97% of particles that are 0.3 microns in diameter or larger. This level of filtration makes them highly effective at removing harmful contaminants like dust, pollen, bacteria, and even certain viruses. For industries that demand the highest levels of air purity, HEPA filters are often the filter of choice.

HEPA filters are constructed using a dense mat of randomly arranged fibers, which creates a complex pathway for particles to navigate. When air passes through, particles are trapped by three main mechanisms: interception, impaction, and diffusion. This structure allows HEPA filters to capture a wide range of airborne particles effectively.

The basic operation of an FFU with a HEPA filter is straightforward but effective. Here’s how it works step-by-step:

1. Air Intake: The FFU’s fan pulls in air from the surrounding environment, which can contain particles, dust, and other contaminants.

2. Filtration: As air moves through the HEPA filter, contaminants are captured, ensuring that only clean, particle-free air passes through.

3. Air Distribution: The filtered air is then evenly distributed into the controlled environment, maintaining a consistent flow of clean air.

4. Continuous Operation: Most FFUs operate continuously to keep contaminant levels low. The fan keeps pulling in and filtering air, maintaining a stable level of air purity.

FFUs with HEPA filters are vital in various industries, each with specific air quality requirements:

1. Cleanrooms: Cleanrooms in industries like semiconductor manufacturing, pharmaceuticals, and biotechnology often require Class 1 to Class 100,000 clean environments. FFUs with HEPA filters maintain these standards by continuously supplying filtered air.

2. Healthcare Facilities: In hospitals, FFUs with HEPA filters are used in isolation rooms, surgical suites, and labs. These units help prevent infections by limiting airborne contaminants.

3. Laboratories: Scientific research labs, particularly those working with sensitive biological or chemical materials, rely on HEPA-filtered FFUs to ensure contaminant-free air.

4. Food Processing: The food industry uses FFUs with HEPA filters in controlled production areas to minimize contamination and extend product shelf life.

5. Aerospace and Electronics: Both aerospace and electronics manufacturing require extreme levels of air purity to protect delicate components from damage. FFUs with HEPA filters are often installed in these production areas to prevent even microscopic particles from disrupting the manufacturing process.

Using FFUs with HEPA filters provides several significant advantages:

1. Improved Air Quality: HEPA filters provide exceptional particle filtration, ensuring clean air in environments where air purity is paramount.

2. Consistent Airflow: FFUs are designed to maintain a steady, uniform airflow. This stability helps maintain the proper pressure and air distribution in cleanrooms and other controlled areas.

3. Energy Efficiency: Modern FFUs are energy-efficient, with some models designed to use less power while maintaining high performance. This efficiency can lead to reduced operational costs in facilities where multiple units are used.

4. Flexible Installation Options: FFUs can be installed in a variety of configurations to suit different spaces and layouts. They can be mounted on the ceiling, walls, or even used in mobile cleanrooms or portable setups.

5. Reduced Noise: Many FFUs are designed to operate quietly, making them suitable for environments where noise levels need to be minimized, such as hospital rooms and labs.

Selecting the appropriate FFU with HEPA filter depends on several factors:

1. Airflow Requirements: Determine the airflow rate required for your space. This rate is typically measured in cubic feet per minute (CFM) and should match the cleanroom’s design specifications.

2. Cleanroom Classification: Your cleanroom’s classification (e.g., ISO Class 5, Class 7) will dictate the level of filtration required. The higher the classification, the more stringent the filtration needs.

3. Noise Level: Consider the noise level of the FFU, especially if it will be used in noise-sensitive environments.

4. Energy Consumption: Look for energy-efficient models to reduce long-term operating costs, especially if you’ll be using multiple FFUs.

5. Maintenance Requirements: Choose FFUs with easily accessible filters and minimal maintenance needs. Some units offer filter change indicators, making it easier to keep track of maintenance schedules.

To keep your FFU with a HEPA filter operating at peak performance, regular maintenance is essential. Here are some maintenance tips:

1. Filter Replacement: Replace HEPA filters as recommended by the manufacturer. Over time, filters can become clogged, reducing airflow and efficiency.

2. Clean the Fan and Housing: Dust and debris can accumulate on the fan and housing. Regular cleaning prevents buildup and ensures efficient performance.

3. Inspect for Damage: Check for any physical damage to the unit, such as cracks or loose components, which could affect airflow and filtration.

4. Monitor Airflow: Some FFUs come with airflow monitors that allow you to track performance. If airflow decreases significantly, it may be time to replace the filter or inspect the fan.

5. Professional Servicing: For large facilities, scheduling regular inspections with a professional technician can help prevent unexpected issues.

The demand for clean air technology continues to grow, and FFUs with HEPA filters are evolving to meet new challenges. Some of the latest trends include:

1. Energy-Efficient Motors: New motor designs consume less energy, which is crucial for facilities using large numbers of FFUs.

2. HEPA and ULPA Hybrid Filters: Some manufacturers are developing hybrid filters that combine HEPA and ULPA filtration to capture even smaller particles.

3. Smart Controls: Advanced FFUs now feature smart controls that allow for real-time monitoring of airflow, filter life, and energy usage, making it easier to manage air quality remotely.

4. Eco-Friendly Materials: The shift towards eco-friendly materials in FFU construction aims to reduce the environmental impact of manufacturing and disposal.

Fan filter units with HEPA filters play an indispensable role in maintaining clean, contaminant-free environments in a variety of industries. Their ability to filter out microscopic particles, maintain steady airflow, and operate efficiently makes them essential for facilities that demand strict air quality standards. As technology advances, FFUs are becoming more energy-efficient, easier to control, and better suited to meet the growing need for clean air. Whether you’re setting up a cleanroom, a hospital isolation room, or a food production facility, an FFU with a HEPA filter is a wise investment in air quality and safety.