January 07, 2025

January 07, 2025

When it comes to maintaining clean air in sensitive environments, HEPA filters and MERV 17 filters are often at the forefront of discussion. Both are designed to capture tiny particles, making them essential in settings such as hospitals, cleanrooms, and industries requiring stringent air quality standards.

In this blog, we’ll explore what HEPA and MERV 17 filters are, how they work, their differences, and where they are commonly used.

HEPA (High-Efficiency Particulate Air) filters are designed to remove at least 99.97% of airborne particles as small as 0.3 microns. This size is considered the most penetrating particle size (MPPS), making HEPA filters incredibly effective at trapping fine dust, pollen, mold spores, bacteria, and even some viruses.

Key Features of HEPA Filters:

- Efficiency: Captures particles as small as 0.3 microns.

- Applications: Used in medical facilities, cleanrooms, airplanes, and residential air purifiers.

- Construction: Typically made from densely packed glass fibers or synthetic materials.

The MERV (Minimum Efficiency Reporting Value) rating system measures a filter’s ability to capture particles of different sizes. It ranges from 1 to 20, with higher numbers indicating better filtration.

A MERV 17 filter is one of the highest-performing filters on the scale. It can capture:

- Particles 0.3 to 1 microns: 99.97% efficiency or higher.

- Particles larger than 1 micron: Virtually 100% efficiency.

In essence, a MERV 17 filter is comparable to a HEPA filter in performance.

While both filters provide exceptional air filtration, their primary distinction lies in standards and testing.

1. Testing Standards:

- HEPA filters must meet stringent international standards, such as EN 1822 or ISO 29463, ensuring their 99.97% efficiency at 0.3 microns.

- MERV filters are rated based on ASHRAE 52.2, which evaluates a broader range of particle sizes.

2. Applications:

- HEPA filters are widely recognized for critical environments like cleanrooms and medical facilities.

- MERV 17 filters are more commonly referenced in HVAC systems, providing a standardized way to classify high-efficiency filters.

3. Cost and Availability:

- HEPA filters tend to be more expensive and are designed for specialized applications.

- MERV filters, including MERV 17, are more commonly available for general HVAC systems.

HEPA Filters:

- Cleanrooms: Ensuring contaminant-free environments for semiconductor manufacturing, pharmaceuticals, and biotech research.

- Healthcare: Maintaining sterile conditions in operating rooms and isolation wards.

- Residential: Enhancing air quality in homes with allergies or asthma concerns.

MERV 17 Filters:

- Commercial HVAC Systems: Delivering high air quality in offices, schools, and public spaces.

- Industrial Applications: Protecting sensitive equipment and processes in factories and labs.

- Hospitals: Supplementing HEPA filters in ventilation systems to meet stringent air quality requirements.

1. Superior Air Quality: Both filters remove tiny pollutants, ensuring clean air for occupants.

2. Health Protection: Traps allergens, bacteria, and viruses, reducing respiratory risks.

3. Compliance: Meets or exceeds regulatory standards for clean air in critical industries.

4. Versatility: Suitable for residential, commercial, and industrial use.

When deciding between HEPA and MERV 17 filters, consider the following:

1. Application Needs: For critical environments like cleanrooms, HEPA filters are mandatory. For general HVAC systems, MERV 17 filters may suffice.

2. Budget: MERV 17 filters are often more cost-effective for less stringent applications.

3. System Compatibility: Ensure your HVAC system can accommodate the pressure drop associated with high-efficiency filters.

1. Professional Installation: Both HEPA and MERV 17 filters require precise installation to ensure optimal performance.

2. Regular Maintenance: Replace filters as recommended to prevent airflow restrictions and maintain efficiency.

3. Pre-Filters: Use pre-filters to capture larger particles, extending the life of HEPA or MERV 17 filters.

HEPA and MERV 17 filters represent the pinnacle of air filtration technology. While their performance is similar, understanding their differences and applications will help you choose the right solution for your needs. Whether you’re protecting sensitive equipment, ensuring compliance in a cleanroom, or improving indoor air quality, these filters provide unmatched reliability.

If you’re ready to upgrade your air filtration system or need expert advice, contact us today to explore our range of high-performance HEPA and MERV filters. Clean air starts with the right filter!

Jul. 11, 2023

What is a HEPA filter in a hospital operating room - What filters are included in an operating room?

Jul. 11, 2023

What is a HEPA filter in a hospital operating room - What filters are included in an operating room?

Oct. 18, 2023

F9 V-Bank Type HEPA Filter

Oct. 18, 2023

F9 V-Bank Type HEPA Filter

May. 29, 2024

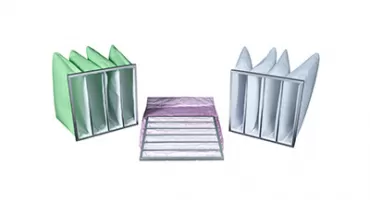

Pocket Air Filters: A Comprehensive Guide

May. 29, 2024

Pocket Air Filters: A Comprehensive Guide