June 02, 2023

June 02, 2023

High flow filter cartridges have emerged as a vital component in various industries, including water treatment, pharmaceuticals, food and beverage, and chemical processing. These specialized filters offer superior filtration efficiency and performance, providing an effective solution for managing large volumes of fluids. In this article, we will explore the key features, benefits, and applications of high flow filter cartridges.

Key Features:

High flow filter cartridges are designed to handle high flow rates and large volumes of fluids while maintaining optimal filtration efficiency. These cartridges possess several key features that contribute to their effectiveness:

1. Large Surface Area: High flow filter cartridges are constructed with a significantly larger surface area compared to traditional filters. This increased surface area allows for greater contact between the fluid and the filter media, enhancing filtration efficiency.

2. High Flow Rates: The design of high flow filter cartridges facilitates the passage of fluids at elevated flow rates. This feature enables efficient filtration without compromising on the filtration quality, thereby reducing processing time.

3. Low Pressure Drop: High flow filter cartridges are engineered to minimize pressure drop across the filter media. By reducing pressure drop, these cartridges ensure a continuous and uninterrupted flow of fluids, optimizing overall system performance.

Benefits:

Utilizing high flow filter cartridges offers several benefits to industries that require efficient and reliable filtration:

Enhanced Filtration Efficiency: The larger surface area and high flow rates of these cartridges enable effective removal of contaminants, such as sediments, particles, and microorganisms, from the fluid stream. This ensures the production of high-quality end products.

Cost Savings: The high flow capabilities of these cartridges allow for the use of fewer filters in a system, reducing the frequency of filter replacements. This results in cost savings in terms of filter procurement, maintenance, and disposal.

Improved Productivity: The ability to handle large volumes of fluids and maintain high flow rates ensures uninterrupted operation, minimizing downtime for filter replacements. This improves overall productivity and process efficiency.

Applications:

High flow filter cartridges find applications in various industries:

Water Treatment: High flow filters are widely used in municipal water treatment plants, desalination plants, and industrial water filtration systems to remove suspended solids, sediment, and other contaminants.

Pharmaceuticals: These cartridges are employed in pharmaceutical manufacturing processes to ensure the removal of impurities, bacteria, and particulate matter, thus maintaining the purity and quality of pharmaceutical products.

Food and Beverage: High flow filters are utilized in the food and beverage industry for clarifying liquids, removing particles, and ensuring microbial control during the production of beverages, dairy products, and processed foods.

Chemical Processing: In chemical processing plants, high flow filters play a crucial role in maintaining the integrity of products by removing impurities, contaminants, and solid particles from process streams.

Conclusion:

High flow filter cartridges offer significant advantages in terms of filtration efficiency, performance, and cost savings. Their ability to handle high flow rates, large volumes of fluids, and provide exceptional filtration makes them an indispensable solution in diverse industries. By incorporating high flow filter cartridges into filtration systems, industries can achieve improved product quality, enhanced productivity, and efficient filtration processes.

Aug. 27, 2024

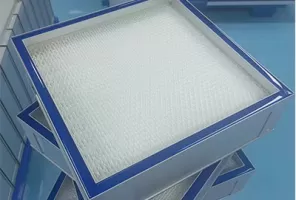

Air Filtration in Cleanrooms

Aug. 27, 2024

Air Filtration in Cleanrooms

Apr. 19, 2024

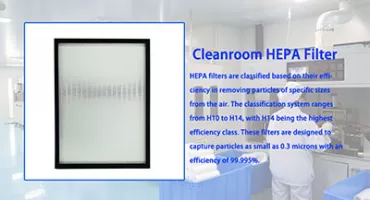

Understanding Cleanroom Filters: The Cornerstone of Controlled Environments

Apr. 19, 2024

Understanding Cleanroom Filters: The Cornerstone of Controlled Environments

Jun. 13, 2024

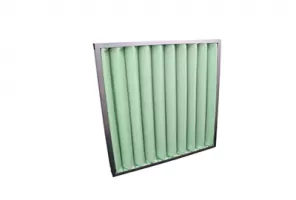

Comprehensive Guide to Panel Air Filters

Jun. 13, 2024

Comprehensive Guide to Panel Air Filters