September 26, 2023

September 26, 2023

The High Temp Pre-Filters ordered by the Indonesian customers have been shipped.

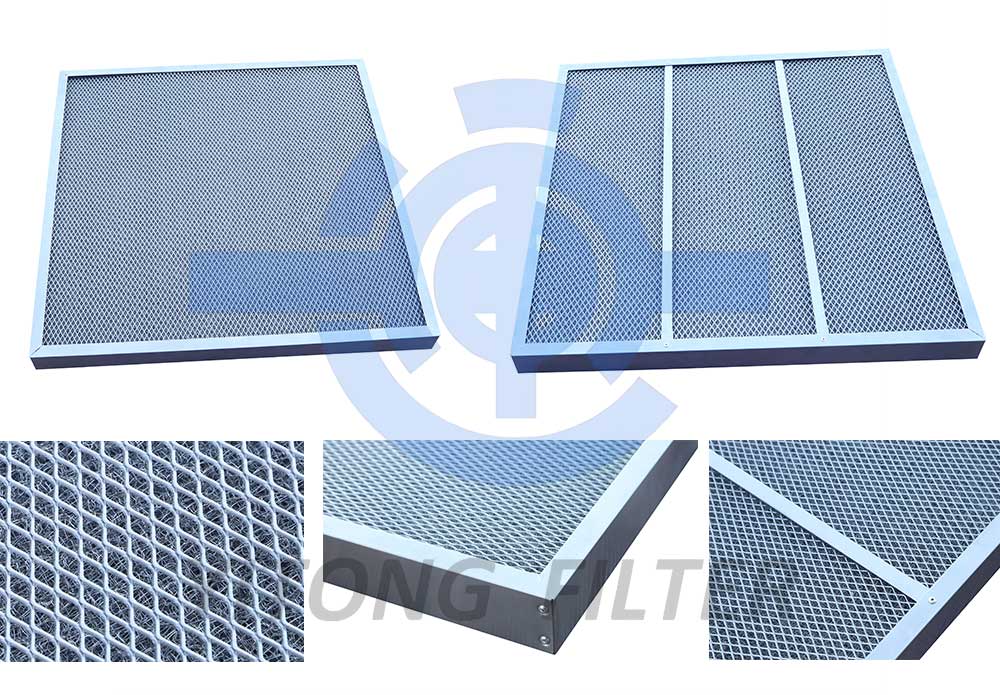

High Temp Pre-Filters Product Detail:

Type: Panel,washable

Frame material: Stainless steel 304

Filter media: Stainless steel 304

Max. Working temp: 110°C/250°C/385°C

Filter class: G1/G2/G3

Standard size: 592X592X47mm

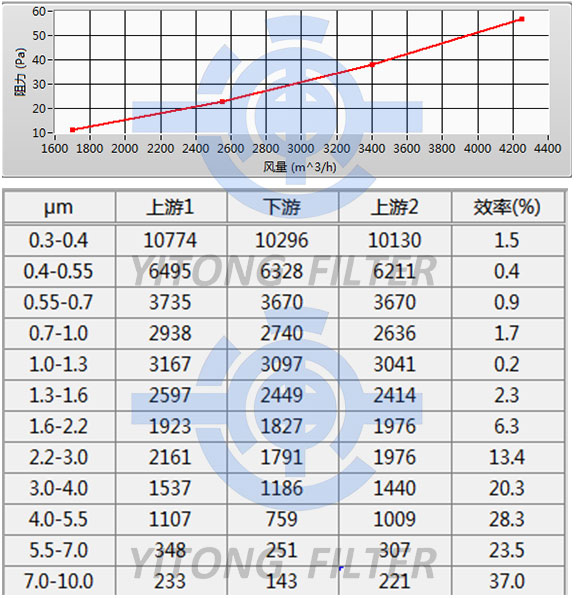

High Temp Pre-Filters Technical Datasheet

| Initial pressure Test Report | ||||

| Air flow(m³/h) | 1700 | 2550 | 3400 | 4250 |

| Velocity(m/s) | 1.27 | 1.9 | 2.54 | 3.17 |

| Initial pressure(≤Pa) | 11.2 | 22.8 | 37.9 | 56.9 |

| Filteration area(m²) | 0.35㎡ | |||

High Temp Pre-Filters Test Report

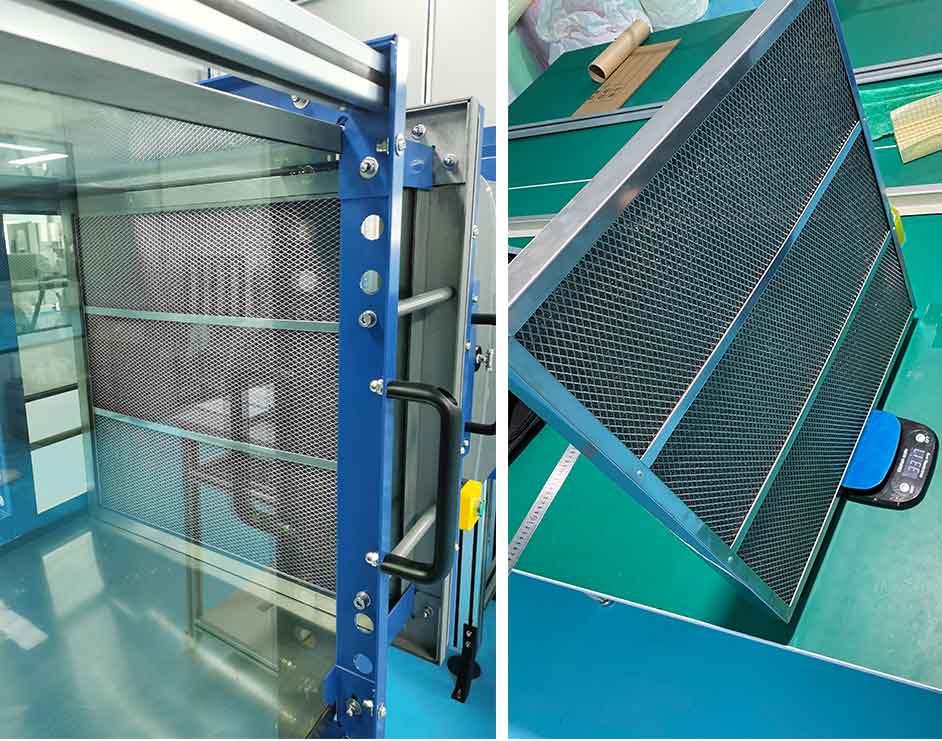

High Temp Pre-Filters Photos

What is a High Temp Pre-Filters?

A high-temp pre-filter, also known as a high-temperature pre-filter, is a type of air filtration component or system designed to remove particles and contaminants from air streams in environments with elevated temperatures. These filters are commonly used in industrial and specialized applications where the air contains high levels of heat, such as in exhaust systems, furnaces, ovens, and other high-temperature processes.

The primary purpose of a high-temp pre-filter is to protect downstream equipment, such as sensitive instruments or more delicate filters, from damage or contamination caused by hot particulate matter or other pollutants in the air. These filters are typically made from materials that can withstand high temperatures without melting or degrading, such as ceramic fibers, high-temperature synthetic materials, or metal mesh.

Some common features of high-temp pre-filters include:

1. High-temperature resistance: These filters are designed to operate effectively in environments where temperatures can reach several hundred degrees Celsius (or even higher in some cases).

2. Particle removal: High-temp pre-filters are capable of capturing various types of particles, including dust, soot, ash, and other contaminants, to prevent them from entering sensitive equipment or downstream filtration systems.

3. Durability: They are built to withstand the harsh conditions of high-temperature environments without breaking down or losing their filtration efficiency.

4. Low pressure drop: High-temp pre-filters are designed to have minimal impact on airflow and system performance, ensuring that they don't impede the operation of the equipment they are protecting.

These filters are often used in industrial processes such as metal smelting, foundries, incineration, and power generation, where high temperatures are generated as a byproduct of the operation. High-temp pre-filters play a crucial role in maintaining the cleanliness and efficiency of equipment in these environments.