May 29, 2024

May 29, 2024

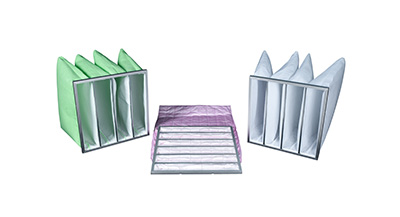

In today’s world, the quality of the air we breathe has become a growing concern. With increasing pollution levels and a heightened awareness of respiratory health, finding effective ways to improve indoor air quality is essential. This guide will provide an in-depth introduction to the installation and use of pocket air filters.

How to Install a Pocket Air Filter

During the installation process of a pocket air filter, ensure the work area is clean and the equipment power is turned off to prevent dust entry. Follow these steps:

1. Open the filter packaging, remove the pocket air filter, and check for any damage or stains. If any issues are found, replace it with a new one.

2. Determine the installation direction of the filter. Usually, there are arrows indicating the airflow direction. Ensure the arrow points towards the inlet side.

3. Close the old filter cover on the equipment or remove the old filter (if any), and clean the installation port of dust and debris.

4. Align the new pocket air filter with the installation port, gently insert and adjust it into place, ensuring the pocket air filter is fully embedded in the frame without any looseness.

5. Use tools or pressing devices to tighten the edges of the pocket air filter, ensuring a good seal to prevent air leakage.

6. After installation, check if the contact between the pocket air filter and the frame is tight and if it is securely fixed.

7. Close the equipment's filter cover, turn on the power, and conduct a test run to confirm the newly installed filter is functioning properly.

Throughout the installation process, always wear protective gloves to avoid direct contact with the pocket air filter, protecting the filter’s effectiveness and ensuring personal safety.

Usage Precautions for Pocket Air Filter

When using pocket air filter, pay attention to the following points:

1. Equipment Placement: Ensure there is enough space around the equipment (no less than 0.3m) and keep it as far away as possible from air outlets and other sources of vibration. Otherwise, it may cause damage to or detachment of the filter cartridge. Also, avoid proximity to high-temperature and high-pressure equipment and environments.

2. Leakage Check: After installation, strictly check all sealing surfaces for air leaks. Repair any defects promptly.

3. Adjust Air Supply Pressure: Adjust the pressure differential valve according to design requirements to achieve the necessary initial and final resistance, or adjust the fan speed to achieve the required initial and final resistance, ensuring sufficient molecular retention capacity.

4. Regular Replacement: Periodically replace non-woven fabric or other consumable materials to extend the service life and ensure high purification efficiency.

5. Routine Maintenance: Regularly remove accumulated dust and other obstacles from the mesh cover to ensure smooth ventilation and avoid conditions that might obstruct machine operation and cause vibrations, thus maintaining good working conditions.

6. Operator Training: Operators must be trained to properly master the operation methods and maintenance of the machine.

7. Handling Issues: If problems arise that cannot be resolved, turn off the power and contact service engineers to avoid unnecessary losses.

In summary, paying attention to detail and promptly addressing any abnormal situations during use can improve work efficiency and extend the filter's service life.

The above information is a reference to the precautions for using pocket air filter.

Any Questions? Give us a call or contact us by e-mail info@yitong-filter.com, our filter experts at any time!

Nov. 06, 2024

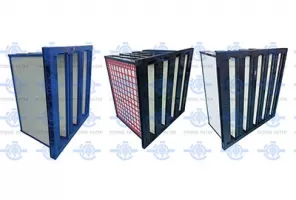

V-Bank Filters: The Ultimate Guide to High-Efficiency Filtration

Nov. 06, 2024

V-Bank Filters: The Ultimate Guide to High-Efficiency Filtration

Oct. 18, 2023

F9 V-Bank Type HEPA Filter

Oct. 18, 2023

F9 V-Bank Type HEPA Filter

Oct. 25, 2023

Application of HEPA filters in the Automotive Painting Industry

Oct. 25, 2023

Application of HEPA filters in the Automotive Painting Industry