February 20, 2024

February 20, 2024

In the fast-paced world of pharmaceuticals, ensuring the purity and safety of products is paramount. One crucial tool in achieving this goal is the High Efficiency Particulate Air (HEPA) filter. These filters play a vital role in maintaining clean and sterile environments throughout various stages of pharmaceutical production. Let's delve into why HEPA filters are indispensable in the pharmaceutical industry.

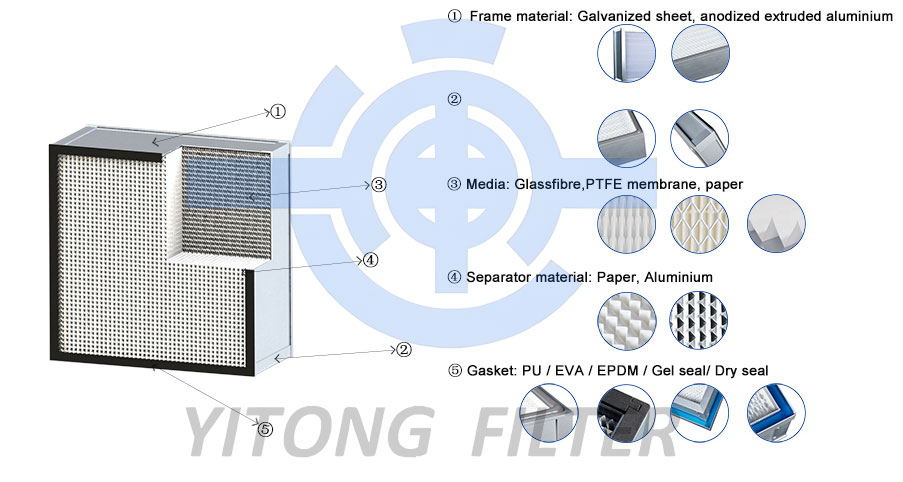

Firstly, what exactly is a HEPA filter? HEPA filters are dense, fibrous mats made of randomly arranged fibers. These fibers trap tiny particles such as dust, pollen, bacteria, and viruses, preventing them from circulating in the air. The efficiency of HEPA filters is remarkable, with the ability to capture particles as small as 0.3 microns with an efficiency of 99.97%.

In pharmaceutical manufacturing facilities, maintaining a sterile environment is non-negotiable. Contamination can compromise the quality and safety of pharmaceutical products, leading to serious health risks for consumers. HEPA filters are instrumental in preventing contamination by removing airborne particles that could potentially contaminate drugs during production.

Cleanrooms, where pharmaceutical products are manufactured, are equipped with HEPA filters in their ventilation systems. These filters ensure that the air circulating within cleanrooms is virtually free of contaminants. This controlled environment minimizes the risk of impurities entering the manufacturing process, resulting in high-quality, pure pharmaceutical products.

Moreover, HEPA filters are utilized in laboratories for research and development purposes. These filters help maintain a controlled environment free from contaminants, ensuring the accuracy and reliability of experimental results. Whether testing new drug formulations or conducting microbial analysis, the integrity of the results depends on the purity of the laboratory environment provided by HEPA filters.

In addition to manufacturing and research, HEPA filters are also essential in storage areas where pharmaceutical products are stored before distribution. By maintaining a clean and sterile environment, these filters help preserve the potency and efficacy of drugs, extending their shelf life and ensuring they remain safe for consumption.

Furthermore, HEPA filters play a crucial role in maintaining the health and safety of personnel working in pharmaceutical facilities. By filtering out harmful airborne particles, HEPA filters help create a healthier work environment, reducing the risk of respiratory ailments and allergies among workers.

In conclusion, HEPA filters are indispensable in the pharmaceutical industry for maintaining clean and sterile environments essential for drug manufacturing, research, and storage. These filters not only safeguard the quality and purity of pharmaceutical products but also contribute to the health and safety of both consumers and personnel. As technology advances and regulations evolve, HEPA filters will continue to be a cornerstone of pharmaceutical manufacturing, ensuring the production of safe and effective medications.

Yitong Filter is a leading air filter manufacturer, offering a wide range of high-quality air filters, including HEPA filters. With more than 20 years of experience, Yitong Filter has become a trustworthy air filtration solution provider in various industries such as hospitals and pharmaceuticals.

By choosing Yitong Filter as your air filter manufacturer, you can expect:

High-quality air filters that meet industry standards

Professionally providing air filtration solutions to various industries

Excellent customer service and technical support

Customized air filter solutions based on your specific needs

Don't settle for less than the best among commercial air filters. Contact Yitong Filter today to discuss your air filtration needs and learn how our range of high-quality HEPA filters can provide the clean air your facility needs.

Nov. 08, 2024

What Types of Filters Are There for Ventilation Systems?

Nov. 08, 2024

What Types of Filters Are There for Ventilation Systems?

Aug. 09, 2023

Differences between F8 and F6 Medium Efficiency Filters

Aug. 09, 2023

Differences between F8 and F6 Medium Efficiency Filters

Jan. 23, 2024

Why HEPA Filters Matter for Clean Indoor Air?

Jan. 23, 2024

Why HEPA Filters Matter for Clean Indoor Air?