July 17, 2023

July 17, 2023

The G4 standard is a criterion used to evaluate the filtration efficiency and performance of primary filter cotton. It is applicable to HVAC (Heating, Ventilation, and Air Conditioning) systems and other air filtration applications. The G4 standard for primary filter cotton refers to the filtration efficiency level that complies with the European standard EN 779. According to this standard, the filtration efficiency of primary filter cotton should be at least 90%, meaning it can filter particles in the air with a diameter equal to or greater than approximately 5 micrometers. It is important to note that this standard is defined based on particle size, so the actual filtration efficiency may vary depending on factors such as the size and density of suspended particles in the air.

In this blog, we provide you with a comprehensive exploration of G4 standard for primary filter cotton, presenting the ultimate guide to G4 standard for primary filter cotton.

What is the filtration efficiency of G4 standard for primary filter cotton?

The filtration efficiency of G4 standard for primary filter cotton is 90%.

How does G4 standard for primary filter cotton differ from other standards?

The difference between G4 standard for primary filter cotton and other standards lies in its filtration efficiency and pore size. The G4 standard requires a filtration efficiency of 90% or higher and a pore size between 5-10 micrometers for primary filter cotton. On the other hand, other standards may require higher filtration efficiency and smaller pore sizes. For example, the F7 standard requires a filtration efficiency between 80-90% and a pore size between 1-3 micrometers. Additionally, different standards have different application areas. The G4 standard is suitable for general air filtration, while the F7 standard is suitable for air purification applications that require higher filtration.

Which types of air filters does the G4 standard apply to?

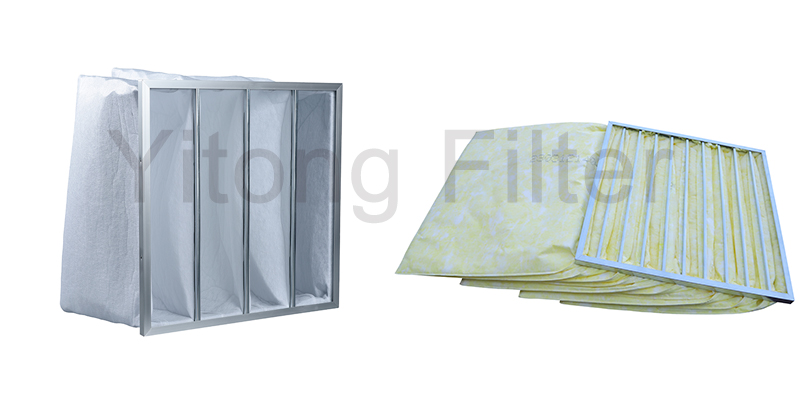

The G4 standard applies to the particle capture efficiency of air filters. Therefore, it is suitable for filters that capture larger particles, such as bag type filters and panel type filters.

How to test primary filter cotton for G4 standard?

Testing primary filter cotton for G4 standard can be done following these steps:

1. Place the primary filter cotton to be tested on the test bed of the testing instrument.

2. Turn on the testing instrument and adjust the testing parameters to meet the G4 standard.

3. Allow the testing instrument to run for a period of time to ensure the accuracy and reliability of the test results.

4. After the test is completed, read the data displayed on the testing instrument, including filtration efficiency, airflow rate, and other data.

5. Compare and analyze the test results with the G4 standard to evaluate the performance of the primary filter cotton.

6. Record and archive the test results for future reference and use.

It is important to note that testing primary filter cotton for the G4 standard requires the use of professional testing instruments, and the operation should be conducted under the guidance of professionals to ensure accuracy and reliability.

A good G4 primary filter cotton plays a crucial role in air filtration. However, without understanding the color meanings and how to choose the right products, the effectiveness of our air filtration can be compromised. Below, we will provide you with detailed information about primary filter cotton.

Color Meanings of G4 Primary Filter Cotton

The color of primary filter cotton is typically white or yellow, and its meaning depends on the type. For G4 primary filter cotton, it is usually made of white or light yellow filter material, indicating that it filters air particles with a diameter between 5-10 micrometers. Yellow filter cotton is often made of fiber materials, which are more common and cost-effective, suitable for industrial and commercial settings. White filter cotton is often made of polyester material, known for its strong antibacterial properties, low resistance, and cost-effectiveness, making it more suitable for places with high air quality requirements, such as medical facilities, production workshops, and office buildings.

Tips for Choosing G4 Primary Filter Cotton

1. Determine the filtration requirements: Different air filtration devices have varying requirements for primary filter cotton. Therefore, before selecting primary filter cotton, it is necessary to determine the filtration efficiency needed. Generally, higher-grade primary filter cotton provides better filtration efficiency.

2. Choose reputable brands and manufacturers: The market offers a wide range of primary filter cotton brands and types, but their quality may vary. To ensure the quality and performance of the product, it is recommended to choose reputable brands and manufacturers.

3. Consider application scenarios and environments: When selecting primary filter cotton, it is important to consider the applicable scenarios and environments. For example, if it will be used in high-temperature environments, heat-resistant primary filter cotton should be chosen. If it will be used in explosive environments, anti-static primary filter cotton should be selected.

4. Understand product details: Before making a purchase, it is necessary to gather information about the product's specifications, quality, density, and materials. These factors will affect the filtration efficiency and lifespan of the primary filter cotton.

In conclusion, when choosing G4 primary filter cotton, it is important to understand its color meanings and consider the selection tips. This ensures that you select the right products and provides better assurance for air filtration.