September 10, 2024

September 10, 2024

In today’s world, where air quality is increasingly scrutinized, the demand for reliable air filtration systems has skyrocketed. Whether it’s ensuring a sterile environment in a hospital or maintaining particle-free air in semiconductor manufacturing, air filters play a critical role. Among the various types of filters available, theAbsolute Filter H14 stands out for its exceptional efficiency and widespread use in industries requiring high levels of air purity.

But what exactly is an Absolute Filter H14, and why should you consider it for your air filtration needs? In this blog, we'll explore the features, benefits, and common applications of the H14 filter to help you understand its importance in modern air filtration systems.

An Absolute Filter H14 belongs to the HEPA (High-Efficiency Particulate Air) filter category and is classified under the EN 1822 standard, which defines the performance of HEPA and ULPA filters. The H14 filter is specifically designed to capture a minimum of 99.995% of particles as small as 0.3 microns, making it one of the most efficient filters on the market. This level of filtration ensures that even microscopic contaminants such as bacteria, viruses, and particulate matter are effectively removed from the air.

H14 filters are typically made from a dense web of glass fibers that trap particles through various mechanisms, such as diffusion, interception, and impaction. While smaller particles are captured via diffusion as they bounce off air molecules, larger particles are intercepted directly by the fibers. This unique multi-layered trapping system allows for unparalleled filtration efficiency.

Compared to other HEPA filters, such as H13, which captures 99.95% of particles, the H14 filter offers a higher level of protection and is commonly used in environments where air quality is critical.

When it comes to air filtration, the Absolute Filter H14 provides several standout features that make it an ideal choice for demanding applications:

High Filtration Efficiency

The H14 filter’s ability to capture 99.995% of particles down to 0.3 microns ensures that even the tiniest harmful substances are filtered out. This includes bacteria, viruses, dust, pollen, and other airborne pollutants.

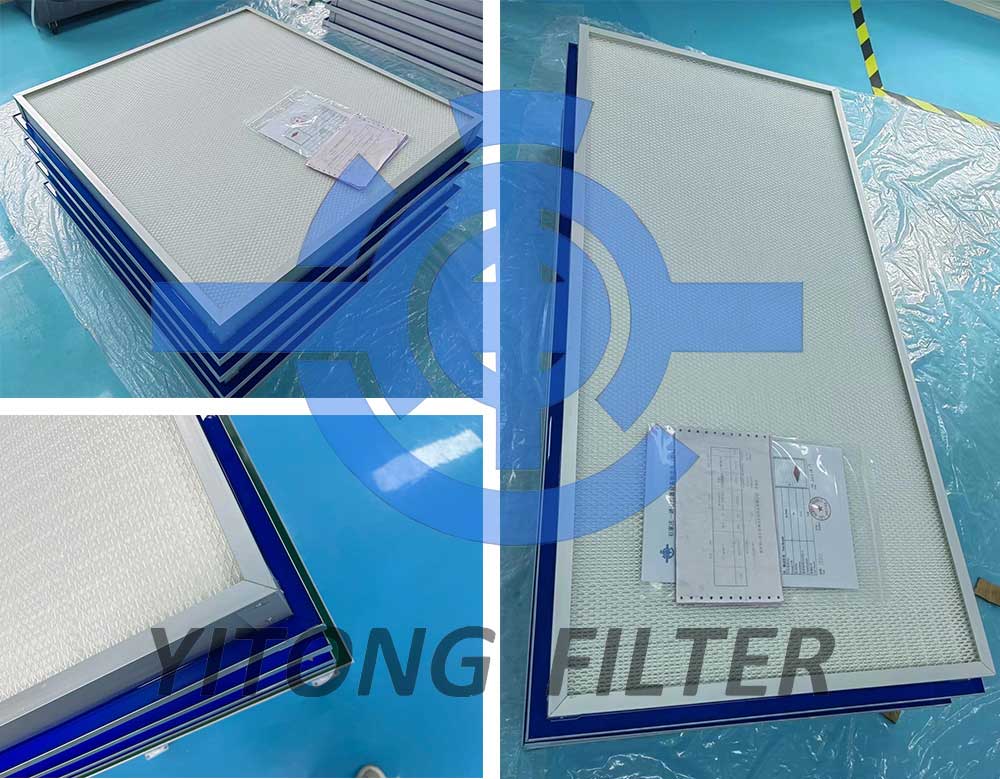

Durable Construction

H14 filters are designed with long-lasting materials such as aluminum, stainless steel, or galvanized steel frames that resist wear and tear. The filter media, usually made from pleated glass fibers, is carefully engineered for maximum strength and performance.

Low Air Resistance

Despite its dense filtration media, the H14 filter offers low resistance to airflow, ensuring efficient operation with minimal pressure drops. This means that the filter can work effectively without placing undue stress on your HVAC system.

Extended Service Life

Absolute Filters H14 are known for their long service life, which can reduce the frequency of replacements and maintenance costs. A well-maintained H14 filter can last for several months or even years, depending on the environment.

The use of Absolute Filter H14 offers several significant advantages, especially in environments that require pristine air quality. Here’s why you might consider investing in one:

Superior Air Purity

The H14 filter’s ultra-high filtration efficiency ensures that your environment is free from nearly all airborne contaminants. This is critical in industries like healthcare, pharmaceutical manufacturing, and food processing, where even the smallest particles can cause significant problems.

Reduced Risk of Contamination

In healthcare facilities, the presence of bacteria or viruses in the air can lead to infections and complications for patients. The H14 filter acts as a barrier, removing harmful microorganisms and reducing the risk of contamination in operating rooms, isolation wards, and laboratories.

Energy Efficiency

Modern H14 filters are designed to work with high airflow rates while maintaining low resistance, which helps reduce energy consumption. This makes them more cost-effective over time, as they allow your HVAC system to run efficiently without excessive strain.

Compliance with Stringent Standards

The Absolute Filter H14 complies with international standards such as EN 1822, making it a trusted choice for industries that need to meet rigorous health and safety regulations.

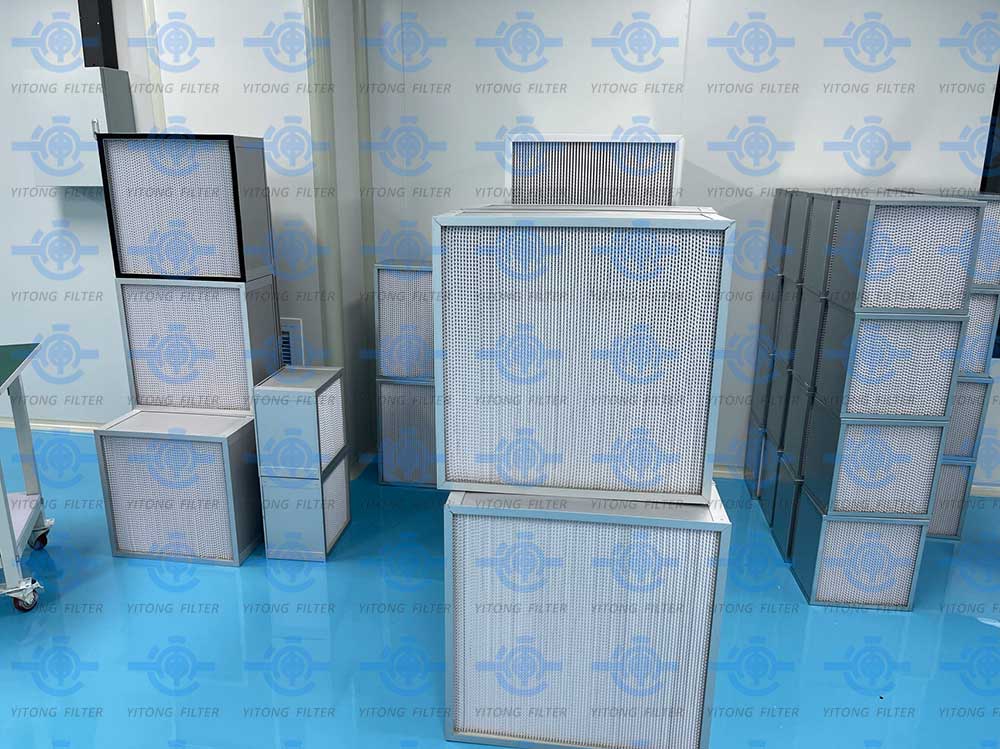

Because of its high efficiency, the Absolute Filter H14 is widely used in various industries where air purity is non-negotiable. Here are some of the most common applications:

Healthcare Facilities

Hospitals and medical centers use H14 filters in operating rooms, intensive care units, and isolation wards to ensure that the air remains free of pathogens. The filters help to create sterile environments where patients are protected from airborne infections.

Pharmaceutical and Biotechnology Industries

H14 filters are essential in cleanrooms and sterile production environments where contamination could compromise product quality and safety. In these industries, maintaining the highest levels of air cleanliness is crucial for preventing product recalls and ensuring patient safety.

Food and Beverage Production

In food manufacturing, air quality is a critical factor in preventing product contamination. H14 filters help to remove airborne bacteria, dust, and other contaminants, ensuring that production environments remain hygienic.

Semiconductor and Electronics Manufacturing

The H14 filter is also used in semiconductor cleanrooms, where even the smallest particle can cause damage to delicate electronic components. These filters help to maintain the ultra-clean environments required for the production of microchips and other high-tech products.

High-Efficiency HVAC Systems

H14 filters are commonly installed in commercial and industrial HVAC systems to provide an extra layer of protection. This ensures that buildings maintain optimal indoor air quality, which is particularly important for spaces such as museums, libraries, and data centers.

When selecting an H14 filter, there are several factors to consider to ensure it meets your specific needs:

Filtration Requirements: Evaluate the level of air purity required for your environment. If you’re operating in a highly sensitive area, such as a cleanroom or medical facility, the H14 filter’s 99.995% efficiency is a must.

Size and Compatibility: Ensure the filter fits within your existing HVAC system or cleanroom design. Improper sizing can reduce efficiency and increase operational costs.

Operational Costs: While H14 filters are highly efficient, they may have higher upfront costs. However, the long-term benefits, such as lower maintenance costs and extended service life, often outweigh the initial investment.

Replacement and Maintenance: Pay attention to the filter’s replacement schedule. Regular maintenance and timely replacement are crucial to ensuring optimal performance.

Installation and Maintenance Tips

To maximize the efficiency of your Absolute Filter H14, proper installation and regular maintenance are crucial:

Professional Installation: Always have a qualified technician install your filter to ensure a tight seal and optimal airflow.

Regular Monitoring: Check your system’s airflow and pressure drop regularly. A significant drop in pressure may indicate that the filter needs to be replaced.

Scheduled Maintenance: Depending on the environment, establish a regular maintenance schedule to inspect and replace filters as necessary. Clean environments typically extend the filter’s lifespan.

Conclusion

The Absolute Filter H14 offers unparalleled air filtration efficiency, making it an essential component for industries requiring ultra-clean environments. Whether you’re in healthcare, pharmaceuticals, food production, or electronics manufacturing, this filter provides peace of mind by ensuring that your air quality meets the highest standards.

To learn more about choosing the right H14 filter for your needs or to explore options for improving your air filtration system, consult with a trusted air filtration expert today.