July 24, 2023

July 24, 2023

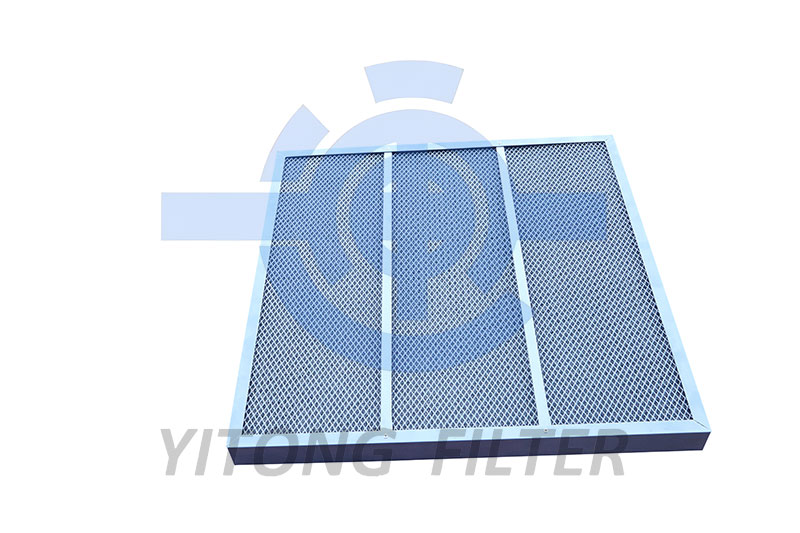

A high-temperature resistant primary efficiency filter is a type of filter material that meets the requirements of primary filtration in high-temperature environments. It achieves preliminary filtration by factors such as the density, thickness, and fineness of the filtering material, with a filtration efficiency of G2 or higher. This filter is widely used in various high-temperature applications, including furnaces, high-temperature fans, paint booths, industrial waste heat recovery, and other high-temperature environments.

The functions of a high-temperature resistant primary efficiency filter include:

1. Capturing particles and dust of 5 microns or larger, as well as various suspended matter.

2. Handling large airflows with low resistance.

3. Having a high dust-holding capacity and excellent resistance to ignition.

4. Demonstrating good chemical properties and low moisture absorption.

5. Serving as a pre-filter for air purification systems in high-temperature environments.

Compared to regular primary air filters, high-temperature resistant primary efficiency filters have higher efficiency, lower resistance, and larger dust-holding capacity. They are commonly used in industrial settings with high-temperature requirements, such as hot air ovens, painting booths, and other industries like automotive, food, daily chemicals, and dust-free ovens.

What are the advantages of high-temperature resistant primary efficiency filters?

High-temperature resistant primary efficiency filters have several advantages, including:

1. Strong temperature resistance, suitable for use in high-temperature environments.

2. Adjustable sieve pore density to meet specific requirements for different applications.

3. High filtration efficiency, effectively filtering large particles like dust, sand, and hair.

4. Easy maintenance and long service life, as they can be repeatedly cleaned and have extended usability.

How should high-temperature resistant primary efficiency filters be maintained?

Regular maintenance of high-temperature resistant primary efficiency filters includes cleaning or replacing the filter media and removing dust from the filter cartridge surface. Additionally, it is essential to inspect the sealing performance of the filter cartridge regularly to ensure a good airtight state and prevent leakage of high-temperature gases that might compromise the filtration effectiveness.

Where are high-temperature resistant primary efficiency filters used?

High-temperature resistant primary efficiency filters are suitable for a wide range of high-temperature applications, including industries like boilers, chemical processing, and iron and steel metallurgy. They are also used in environments that require air purification in high-temperature conditions, such as hospitals and laboratories.

As technology advances, high-temperature resistant primary efficiency filters are likely to become more intelligent, efficient, and sustainable. The integration of artificial intelligence may allow for automatic adjustments based on temperature changes, further improving operational efficiency. Additionally, with increasing awareness of environmental protection, these filters will find broader applications in various industries.

In modern industrial settings, high-temperature resistant primary efficiency filters play an indispensable role in high-temperature environments. As technology and environmental consciousness continue to grow, these filters will be even more widely used due to their numerous advantages and versatile applications.

Aug. 15, 2024

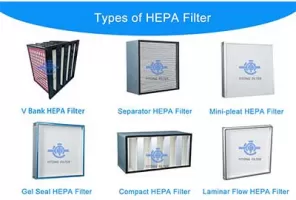

Approved vs. Standard HEPA Filter Types: Making the Right Choice

Aug. 15, 2024

Approved vs. Standard HEPA Filter Types: Making the Right Choice

Aug. 23, 2023

A Detailed Explanation of F5 Bag Air Filter

Aug. 23, 2023

A Detailed Explanation of F5 Bag Air Filter

Jul. 07, 2023

Application and Buying Guide for HEPA Filters

Jul. 07, 2023

Application and Buying Guide for HEPA Filters