November 14, 2024

November 14, 2024

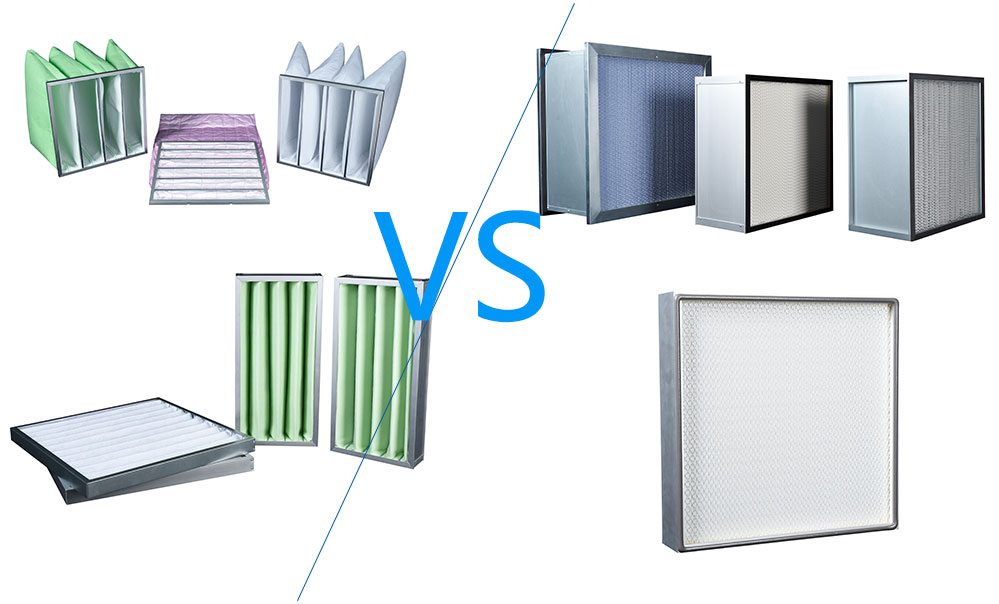

When it comes to air filtration, there are many different types of filters designed to capture various particles in the air. Two common types are pre-filters and fine filters, and while both serve similar purposes, they have distinct differences that make them suitable for different applications.

In this blog post, we’ll explore the key differences between pre-filters and fine filters, how each type works, and when you might need to use one over the other. By the end, you’ll have a better understanding of how these filters work and why both are important in the overall air filtration process.

A pre-filter is the first line of defense in an air filtration system. It is designed to capture larger particles in the air before they can reach the more delicate, finer filters that typically follow in the filtration process. Pre-filters are used to protect finer filters, such as HEPA (High-Efficiency Particulate Air) filters, from becoming clogged with larger debris.

- Larger Pore Size: Pre-filters are typically designed with larger pores that allow them to capture larger particles such as dust, hair, pet dander, and larger dirt particles.

- Primary Function: The main purpose of a pre-filter is to remove these large particles from the air before the air passes through a more expensive, more delicate filter, like a fine filter or HEPA filter.

- Material: Pre-filters are often made from materials such as foam, polyester, or metal mesh. These materials are designed to capture larger particles while still allowing for adequate airflow.

- Maintenance: Because pre-filters capture larger debris, they tend to accumulate dirt more quickly and need to be cleaned or replaced more frequently than fine filters.

Pre-filters are especially important in environments where large particles are common, such as in industrial settings, homes with pets, or places with high dust levels. They are often used in HVAC systems, air purifiers, and even vacuum cleaners. By catching the larger particles upfront, they help extend the lifespan of more expensive filters and improve the overall efficiency of the filtration system.

A fine filter is designed to capture much smaller particles that are not visible to the naked eye. These filters typically use a higher density of fibers to trap smaller contaminants such as pollen, smoke, bacteria, viruses, and fine dust particles. Fine filters are used in conjunction with pre-filters to ensure that both large and small particles are effectively removed from the air.

- Smaller Pore Size: Fine filters have much smaller pores compared to pre-filters. These smaller pores allow them to capture smaller particles, such as microscopic dust and allergens.

- Higher Efficiency: Fine filters are designed to be highly efficient at removing very fine contaminants, which are often the most harmful to health, especially for individuals with allergies, asthma, or other respiratory conditions.

- Materials: Fine filters are usually made from materials like pleated paper, fiberglass, or other high-density media designed to trap small particles while still allowing air to pass through.

- Longer Lifespan: Fine filters, due to their ability to capture smaller particles, generally have a longer lifespan than pre-filters. However, their efficiency can be reduced if the pre-filter is not maintained and larger particles clog them over time.

Fine filters are essential in environments where air quality is a primary concern, such as in hospitals, laboratories, clean rooms, and homes of people with respiratory issues. They are also used in commercial and industrial applications where high levels of fine dust or fumes are present. These filters ensure that even the tiniest particles, which might pose health risks, are captured.

While both pre-filters and fine filters are used to improve air quality, there are some key differences between the two types:

1. Particle Size Captured:

- Pre-Filters: Capture larger particles such as dust, hair, pet dander, and debris.

- Fine Filters: Capture smaller particles, including pollen, smoke, bacteria, and fine dust.

2. Role in the Filtration Process:

- Pre-Filters: Act as a first stage in the filtration process, capturing larger particles to prevent them from clogging the fine filters.

- Fine Filters: Are the second stage in the filtration process, designed to capture smaller, more harmful particles after the pre-filter has done its job.

3. Efficiency:

- Pre-Filters: Less efficient in capturing small particles, as they are designed primarily for larger contaminants.

- Fine Filters: Highly efficient in capturing small particles, offering a higher level of filtration.

4. Material and Construction:

- Pre-Filters: Made from materials such as foam, polyester, or metal mesh, with a loose structure to capture larger debris.

- Fine Filters: Made from finer, denser materials like pleated paper, fiberglass, or activated carbon to capture smaller particles.

5. Maintenance:

- Pre-Filters: Require more frequent maintenance, such as cleaning or replacement, due to the large particles they capture.

- Fine Filters: Require less frequent maintenance but should be replaced when they reach the end of their lifespan or when their efficiency decreases.

In an air filtration system, pre-filters and fine filters work in tandem to maximize the efficiency of the system. The pre-filter captures large particles, which helps to prevent the fine filter from becoming clogged too quickly. This reduces the overall strain on the fine filter and allows it to focus on removing smaller contaminants from the air.

For example, in an air purifier, the pre-filter will first capture dust, hair, and other large particles, allowing the fine filter to focus on capturing allergens, smoke, and microscopic dust. This dual-layer filtration ensures that the air is as clean as possible.

Pre-filters are commonly used in:

- HVAC systems: To protect expensive HEPA filters or other fine filters in commercial and residential settings.

- Air purifiers: To extend the lifespan of the main filter by catching larger particles.

- Vacuum cleaners: To prevent larger debris from clogging the vacuum’s motor.

Fine filters are used in:

- Air purifiers: To remove allergens, bacteria, and other small particles from the air.

- Industrial applications: In environments like factories or clean rooms, where fine dust and contaminants are prevalent.

- Hospitals: To improve air quality for patients, especially those with respiratory issues.

In summary, both pre-filters and fine filters play essential roles in improving indoor air quality. Pre-filters are designed to capture larger particles, protecting fine filters from becoming clogged and extending their lifespan. Fine filters, on the other hand, are designed to capture smaller, more harmful particles, ensuring that the air you breathe is as clean and safe as possible.

Understanding the difference between these two types of filters is important when selecting the right air filtration system for your needs. Whether you're looking to improve the air quality in your home, workplace, or industrial setting, combining pre-filters and fine filters can provide an effective solution for maintaining a healthier, cleaner environment.

If you’re considering upgrading your filtration system, remember to choose both a high-quality pre-filter and a fine filter to ensure maximum efficiency. Proper maintenance, such as regular cleaning and replacement, is also key to keeping your system working optimally.