August 20, 2024

August 20, 2024

HEPA filters are known in the industry as absolute HEPA filters. From the acronym High-Efficiency Particulate Air, these filters are named for their absolute efficiency in capturing particles. These filters have an excellent particle capture system and are especially suited for environments where high air purity is required.

H13 and H14 filters are both high-efficiency air filter classes, and European Standard 1822 defines the testing and categorization of High-Efficiency Particulate Air (HEPA) and Ultra Low Permeable Air (ULPA) filters. H13 and H14 are defined as medical-grade HEPA filters that typically capture 99.95% to 99.995% of particles.

Although both H13 and H14 are considered medical-grade air filters, there are significant differences. It is important to consider the differences when choosing a filter or it will affect the overall air quality.

H13 filters have a filtration efficiency of 99.95% and can remove airborne particles with a diameter of 0.3 microns, including pollen, dust, pet dander, and mold spores, and also capture particles such as bacteria and viruses, which is beneficial for respiratory illnesses, and is therefore sometimes referred to as a medical-grade air filter.

H14 filters can capture 99.995% of airborne particles down to 0.1 micron. H14 filters are typically used in laboratories, cleanrooms, medical facilities, and other industrial environments that require extremely high air purity.

The main difference between H13 and H14 filters lies in their filtration efficiency, the filtration efficiency of H14 is slightly higher than that of H13, so there is a difference between them in terms of usage, H13 is generally used for household and commercial air purification, such as HVAC, air purifiers and vacuum cleaners, etc. H14 filters are generally used in environments where the air purity is extremely high, such as the production environment of electronic products and laboratories.

| Standard | H13 Filter | H14 Filter |

| Efficiency | ≥99.95% | ≥99.995% |

| Particle | 0.3μm | 0.1μm |

| Application | Domestic and commercial (HVAC, air purifiers) | Ultra-clean air environment (laboratories, operating rooms, hospitals, etc.) |

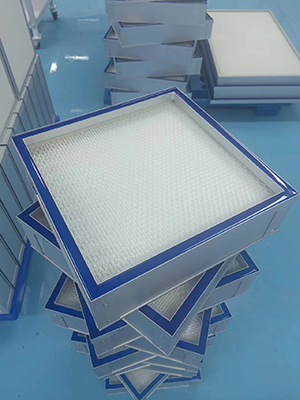

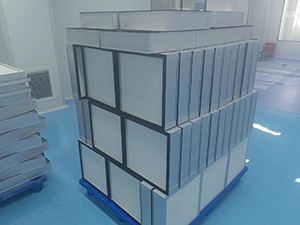

High-efficiency air filters, also known as absolute high-efficiency air filters, are one of the most effective industrial filters in the air treatment category. The outer frame of HEPA filters is usually made of aluminum, galvanized plate, stainless steel, and other metal plates, and the gasket materials are PU / EVA / EPDM / Gel seal / Dry seal / Knife edge, which are made of glass fiber, PTFE and other filter materials in a pleated manner, and are generally classified into compartmentalized air filters and compartmentless air filters.

HEPA filters are engineered to eliminate microscopic pathogens and particles, effectively removing a variety of airborne contaminants, including pollen, dust particles, fibers, suspended gases, aerosols, mites, and viruses. They offer sufficient protection against airborne virus risks, contributing to the creation of a healthy environment.

Some fields are regulated by governmental organizations such as ANVISA and ABNT, which have strict standards for environmental cleanliness, and this is where HEPA filters come into play.

HEPA filters remove airborne particles, which is especially important for maintaining air quality, especially in hospitals, operating rooms, laboratories, and other places that require high levels of air cleanliness. In addition, to airborne pollutants, viruses, and other health hazards, high-efficiency air filters can reduce the presence of these pollutants in the air, thereby reducing the risk of health problems, especially for respiratory diseases and allergy sufferers are very friendly.

HEPA filters can also prevent cross-infection, especially in the pharmaceutical and medical facilities industry, it is particularly important to prevent the spread of pollutants, and HEPA filters can effectively avoid the spread of pollutants to other areas causing cross-infection.

HEPA filters can be used in industrial environments because of their ability to reduce airborne pollutants, which can play a good role in protecting the machines that may be damaged by airborne micro-particles.

In conclusion, HEPA filters have become the best choice for air treatment in high cleanliness environments due to their ultra-high filtration efficiency and wide range of application scenarios as well as their reliable performance and compliance with strict international standards. This makes them widely used in various scenarios such as medical, industrial, household, etc., effectively improving air quality and human health.