Made from hydrophilic PVDF membrane. It is ideal for the filtration of nutrient solution, biological reagent, sterile vaccine, etc.

The hydrophilic polyvinylidene fluoride pleated filter cartridge is made of hydrophilic polyvinylidene fluoride membrane material. The unique extremely low protein adsorption performance of PVDF makes it especially suitable for the filtration of culture medium, biological reagents, sterile vaccines, etc.

● Filtration of blood products

● Biological reagent filtration

● Medium filtration

● Vaccine filtering

● Sterilization filtration

| Construction | Materials |

| Membrane | Hydrophilic PVDF |

| Support layers | Polypropylene |

| Inner core | PP/PVDF/Stainless Steel |

| Outer core | Polypropylene/PVDF |

| End Cap | Polypropylene |

| O-ring | Silicone/Viton/EPDM/PEFE |

| Outer diameter | 68mm、69,mm (2.75") |

| Inner diameter | 33mm(1.3") |

| Length (inch) | 5, 10, 20, 30, 40 |

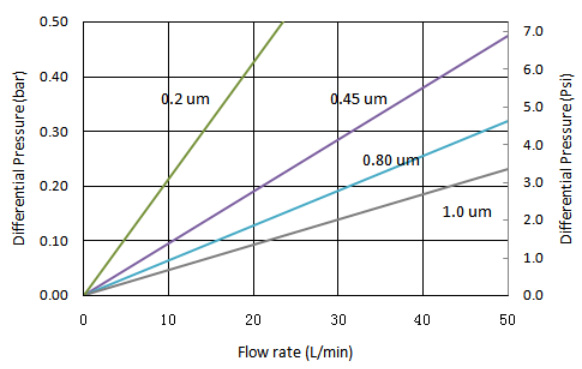

| Removal ratings (µm) | 0.1, 0.22, 0.45, 1.0, 3.0,5.0 |

| Effective Filter Area | ≥0.65㎡/10in |

| Maximum operating temperature | 80 ˚C / 176 ˚F |

| Maximum forward differential pressure | 0.4MPa @ 23 ˚C /58.8 psid @ 73.4 ˚F |

| Steam sterilisation | 121℃/30min |

| Endotoxin | ≤0.25EU/ml |

| Dissolved matter | ≤30mg/10in |

| Integrity | Inspection of each filter element |

1. The integrity of our products is tested to 100%.

2. Our products feature absolute rated and carefully controlled pore size distribution for superior and consistent bacterial retention.

3. They can be autoclaved or steam sterilized on-site.

4. The heavy-duty molded cage offers superior structural strength.

5. The PTFE membrane is highly resistant to chemicals.

6. This product offers a low pressure drop and a high flow rate.

● Filtration of blood products

● Biological reagent filtration

● Medium filtration

● Vaccine filtering

● Sterilization filtration