Mainly used in ventilation system; intercept particles, dust, bacteria, etc. Long service life and stable performance for industrial air filters. Energy-saving and affordable price for commercial air filters.

Classifying air filters (ISO-16890 & EN1822)

Coarse filters (G1-G4), Medium filters (F5-F7), Fine filters (F8/F9), Efficiency particular air filters (H10-H12), High efficiency particular air filters (H13/H14), Ultra low penetration air filters (U15-U17).

We have full replacements for gas turbine air filtration system from major international brands.

Ventilation Air Filters are crucial components in HVAC (Heating, Ventilation, and Air Conditioning) systems, designed to remove contaminants from the air and ensure clean, healthy indoor environments. These filters improve air quality by trapping dust, pollen, bacteria, and other airborne particles, making them essential for both residential and industrial applications.

Types of Ventilation Air Filters:

1. HEPA Filters (High-Efficiency Particulate Air):

- Efficiency: Capture 99.97% of particles as small as 0.3 microns.

- Applications: Hospitals, cleanrooms, laboratories, and environments requiring stringent air quality standards.

2. MERV-Rated Filters (Minimum Efficiency Reporting Value):

- Efficiency Levels: Rated from 1 to 16; higher MERV ratings indicate better filtration.

- Applications:

- MERV 1-4: Basic residential filters for dust and pollen.

- MERV 5-8: Improved residential and commercial applications.

- MERV 9-12: Superior residential, better commercial, and industrial use.

- MERV 13-16: Best for hospitals, surgery rooms, and clean environments.

3. Activated Carbon Filters:

- Function: Remove odors, gases, and VOCs (volatile organic compounds).

- Applications: Commercial kitchens, laboratories, and areas requiring odor control.

4. Pleated Filters:

- Design: Pleated structure increases surface area, enhancing filtration efficiency.

- Applications: Common in residential and commercial HVAC systems.

5. Electrostatic Filters:

- Mechanism: Use static electricity to attract and trap particles.

- Applications: Residential use, especially for individuals with allergies.

Key Benefits of Ventilation Air Filters:

1. Improved Indoor Air Quality (IAQ):

Removes pollutants, allergens, and pathogens, creating a healthier environment.

2. Energy Efficiency:

Clean filters improve airflow, reducing strain on HVAC systems and lowering energy costs.

3. System Longevity:

Protects HVAC equipment from dust and debris, extending the system’s lifespan.

4. Enhanced Comfort:

Maintains consistent airflow and temperature control, contributing to a more comfortable indoor environment.

5. Reduced Maintenance Costs:

Regularly replacing filters prevents system malfunctions, reducing repair costs.

Applications:

- Residential: Homes and apartments for improved comfort and health.

- Commercial: Offices, shopping malls, and hotels to ensure clean air and compliance with health regulations.

- Industrial: Factories and warehouses to protect equipment and personnel.

- Healthcare: Hospitals and clinics for infection control.

- Educational Institutions: Schools and universities to maintain healthy learning environments.

Choosing the Right Ventilation Filter:

When selecting a ventilation air filter, consider:

- Air Quality Needs: Assess pollutant levels and specific contaminants.

- Filter Efficiency: Match the MERV rating or HEPA requirements to your needs.

- System Compatibility: Ensure the filter fits your HVAC system specifications.

- Maintenance Frequency: Balance filter efficiency with ease of replacement and cleaning.

Why Choose Yitong Filter?

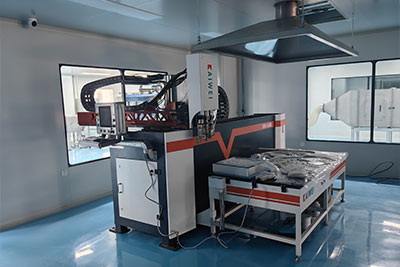

Our workshop

HEPA filters processed in clean room; Coarse filters and Medium filters processed in clean workshop. Whole set modern manufacturing equipment.

Our manufacturing facilities

Laboratory instrument: Air filters performance testing system of general ventilation ISO-16890

Service: Testing of air flow, initial pressure drop, final pressure drop, filter efficiency, dust holding capability and constant humidity.

Automated HEPA filters scanner test system EN1822-4

Service: Testing of air flow, initial pressure drop, filter efficiency and leakage or not.

Quality control

Pressure drop / Air flow / Filter class / Integrity / Humidity resistance tested service preferred

Tested in our laboratory under ISO16890 / EN 1822 / ASHRAE 52.2 / EN 779

Application

Cleanroom ventilation filters in pharma industries, food processing, micro-electronics, etc.

Air purification of hospitals: operating room, ICU, NICU, Negative pressure ambulance, etc.

Air intake filter of Gas Turbines, Fan, etc.

Office building, Metro, Residence, Commercial building